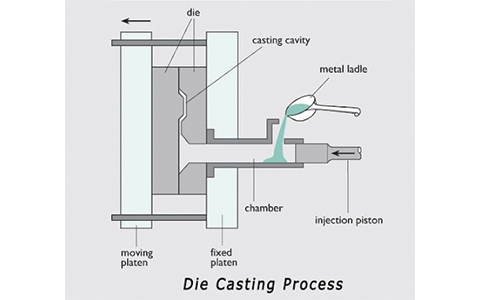

For the casting of metal items, die casting is a common production technique. There are two primary types of die casting processes, and there are other process design variations.

Die casting is the process of applying tremendous pressure on molten metal to push it into mold cavities. The method works well for the quick fabrication of large metallic items that only need minor machining after production, which is why many medical molding companies and medical plastic manufacturers are using it.

What is Die Casting?

Die casting is an automated casting method in which the liquid melt is forced into a mold at a high filling speed (up to 540 km/h) and pressure (150 to 1200 bar). Usually, low melting-point alloys are employed. Because permanent metal molds are utilized instead of, say, sand molds that must be destroyed after casting, this casting process is especially well suited for series and mass manufacturing of components. Low wall thicknesses allow for the production of substantial and intricate components.

Types of Die Casting

The aim of all die casting process varieties is to cast a mold using injected molten metal. Various die casting processes may produce better results than competing techniques depending on the type of molten metal, the part geometry, and the size of the part. Here are the types of die casting.

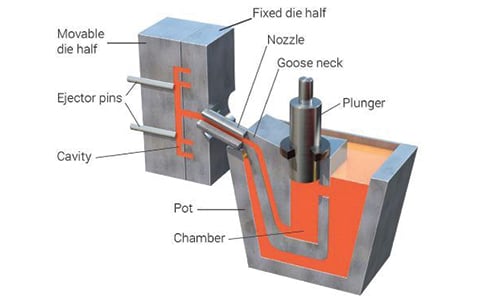

Hot-Chamber Die casting

- What is Hot-Chamber Die Casting

The more well-known of the two primary die-casting techniques is hot-chamber die casting, also referred to as gooseneck casting or hot casting.

- Hot-Chamber Die Casting Process

The molten metal supply is linked to the die casting machine during the hot chamber die casting process and plays a crucial role in this kind of operation. Below, we’ll walk you through the steps one by one.

- Metal liquid floods the heated chamber: Over the source of molten metal is where the shot cylinder, which drives the injection stroke, is situated. This shot cylinder is attached to the plunger by a plunger rod. At the start of a casting cycle, the plunger is at the top of the hot chamber and makes contact with the molten material. In this configuration, the intake apertures allow the liquid metal to fill the chamber.

- The plunger depresses: When the cycle begins, the shot cylinder pulls the plunger downward, forcing it to go beyond the intake ports and obstruct the flow of liquid metal into the heated chamber. The hot chamber currently has the ideal volume of molten metal for the shot that will fill the mold and create the casting.

- The plunger continues to descend: The liquid metal is compelled into the die by further depressing the plunger. The pressure required in hot chamber die casting to force the molten metal into the die normally ranges from 700 to 5,000 pounds per square inch (psi). This pressure is maintained for however long the casting needs to solidify.

- In order to position itself for the upcoming cycle, the plunger reverses and moves back to the top of the heated chamber, where it was originally located. The intake ports are once more made visible, which enables the molten metal to enter and fill the chamber.

- Advantages of Hot-Chamber Die Casting

The most significant advantage of hot chamber die casting versus cold chamber die casting may be the significantly shorter cycle time. As a result, die casting businesses are able to produce more goods in less time, increasing their production and efficiency as well as their ability to satisfy customers.

Additionally, this method offers the following benefits:

- Because there is less metal waste, it is more environmentally friendly.

- increased effectiveness as a result of the machine’s internal melting pot

- decreased porosity

- Because only low-melting-point metals are chosen, machines will last longer.

- Disadvantages of Hot-Chamber Die Casting

Porosity is the fundamental problem with a high-pressure die casting process. However, by employing an evacuated chamber and particular application methods, this can be minimized. Die casting cannot be fully heated since doing so will cause the metal’s surface to develop blisters because pores are present on the surface.

The high initial start-up costs associated with installing the die-casting machinery are another drawback.

Cold-Chamber Die Casting

- What is Cold-Chamber Die Casting

Metals with high melting points are best manufactured using the cold chamber die casting process, which is why it is in high demand with laboratory consumables manufacturers and medical contract manufacturers. Typically, this will involve copper, brass, zinc, aluminum, and alloys of those metals. An outside furnace and a ladle for pouring the molten metal are necessary for cold chamber die casting.

Methods for cold chamber die casting are renowned for their capacity to create metal castings that are denser.

- Cold-Chamber Die Casting Process

Metals having high melting points and corrosive characteristics are best suited for cold chamber die casting. By separating the melting pot from the injector parts, cold chamber die casting addresses the corrosion issue better than hot chamber die casting.

Melted metal is ladled into the shot chamber through a pouring hole from the furnace to start the operation. Next, metal is pushed through the hot chamber and into the die by the plunger under pressures between 2,000 and 20,000 psi.

In a separate furnace, metal is first heated to a molten condition in cold-chamber die casting. The molten metal is then brought to the casting machine and fed into the chamber of the machine. The device pushes the molten metal into the mold cavity using a pressured plunger. Cold chamber die casting is clearly distinguished from hot chamber casting by this independent technique.

- Cold-Chamber Die Casting Advantages

Compared to other manufacturing methods, cold chamber die casting is a powerful, economical process that can produce a wide variety of forms and components. Long-lasting parts can be produced using the cold chamber die casting method, and they can be crafted to match the surrounding part’s aesthetic.

The following are just a few of the immediate advantages that the cold chamber die casting method can offer:

- Increased Strength & Weight

- Dimensional Accuracy & Stability

- High-Speed Production

- Cold chamber die castings have integral fastening components like bosses and studs, which simplifies assembly. External threads can be cast, holes can be cored to drill diameters, etc.

- Multiple Finishing Methods

- Cold-Chamber Die Casting Disadvantages

The use of cold chamber die-casting has a few notable drawbacks. First off, compared to hot chamber die-casting, this technology has a slightly longer manufacturing cycle. This is due to the possibility that the molten substance in the separate chamber will cool before the clean room injection molding. In addition, compared to hot chamber die casting, it necessitates an additional step.

High levels of oxidation and other impurities in cold-chamber die-casting are another drawbacks. During the process, the molten material is exposed to these impurities, which has an effect on the final product’s quality.

Pressure Die Casting

- What is Pressure Die Casting

Pressure die casting is a quick, dependable, and economical manufacturing process for the production of massive volumes of net-shaped, precisely specified metal components.

- What is Pressure Die Casting Process?

In essence, the pressure die casting technique involves pouring a molten metal alloy under high pressure into a steel mold (or tool). This quickly solidifies (between a few milliseconds and a few seconds) to create a component with the shape of a net. Then it is mechanically removed.

- Pressure Die Casting Advantages

- the ability to accurately and in large quantities make metal components that are similar.

- cost-effective method for producing castings in large quantities.

- For speedier production, molten metal solidifies in a matter of seconds or even milliseconds.

- before needing to be changed, can create dozens or even millions of components.

- Suitable for a variety of applications.

- Pressure Die Casting Disadvantages

- requires sophisticated and pricey equipment.

- The setup requires a large financial outlay.

- When comparison to gravity die casting, is rather rigid.

- Less suitable for small production runs or individual casting, which increase in cost proportionally as the number of them decreases.

Low Pressure Die Casting

- What is Low Pressure Die Casting

Molten metal is poured into a die-casting mold using low pressure in LPDC. Due to the continual filling of the die cavity during the shrinking process, it is extremely precise (solidification). In other words, it makes up for the volume drop. Reduced oxide formation, increased porosity, and greater uniformity of the molten metal from top to bottom are other characteristics.

- Low Pressure Die Casting Process

Low-pressure die casting replaces gravity with low pressure, typically 20-100 kPa (2.9-14.5 psi), to fill a die. It features a distinctive setup and utilizes a number of pieces of equipment, unlike the conventional die casting method.

The melting furnace, which melts the metal alloys and raises them to the casting temperature, is where the process starts. Aluminum, for instance, has a casting temperature range of 710–7200C. The molten metal will then be transferred to a holding furnace beneath the mold, serving as a vessel and keeping the liquid at the casting temperature.

The molten metal is forced into the mold through a riser tube by low pressure. Until the molten metal solidifies in the die cavity, the liquid metal flows under steady pressure. The pressure is removed after solidification, and the remaining molten metal is recycled by returning through the riser tube to the holding furnace. Finally, once the mold has cooled, the casting can be readily removed.

- Low Pressure Die Casting Advantages

Due to its many benefits, low pressure die casting (LPDC) is a widely used die casting technique. Here are a few benefits of the procedure.

- High Precision

- It Produces Extremely Pure Castings

- It can be formed well

- Crystallization

- Low Pressure Die Casting Disadvantages

Although low-pressure die casting is the best method for getting precise results, it has drawbacks as well.

- Sluggish Casting Cycle

Its slower cycle as a result of the low pressure is one drawback. As a result, there are few parts that can be manufactured and those that can be expensive.

- Eroded Metal Component

Eroded aluminum casting forms can happen when molten metal contacts a piece of equipment made of metal. High maintenance expenses may result from this, especially in complex production environments. Additionally, the components of the metal component of the equipment may enter the liquid metal, influencing performance.

- Unsuitable for the Production of Thin-walled Parts

The method allows for castings with a minimum wall thickness of roughly 3mm. Hence, high-pressure die casting is better suited to producing parts with thin walls.

High Pressure Die Casting

- What is High Pressure Die Casting

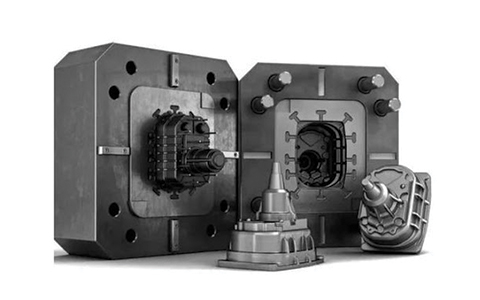

In the process of high-pressure die casting, molten metal is pushed through a sealed mold chamber while under pressure. Until the metal solidifies, it is held in place by a strong compressive force (true die fitted in a hydraulic machine).

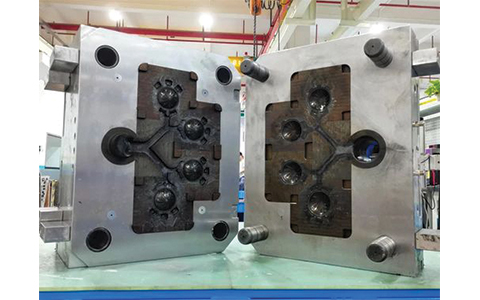

- High Pressure Die Casting Process

The manufacturing process of high-pressure die casting (HPDC) is incredibly effective for creating a variety of product types. High pressure and speed are applied to the molten metal as it is forced into a steel die cavity. Both of the die’s stationary and moving halves are mounted to the platens of the die casting machine.

The molten metal is injected into the closed steel die at the injection end of the die casting machine using hydraulics and pressurized gas. The die casting machine additionally incorporates a clamping end that absorbs injection pressure and holds the die closed as the part solidifies using hydraulics and mechanical toggles. The procedure can solidify molten metal into a part with a close-to-net shape in a matter of seconds.

Aluminum, zinc, and magnesium are the three main metal groups employed in this die casting method. CWM uses both cold chamber and hot chamber high-pressure die-casting techniques to cast all three metals.

- High Pressure Die Casting Advantages

Large, light-alloy parts may be produced quickly and effectively in huge volumes using high-pressure die casting. The HPDC method also produces products with the best mechanical qualities, high homogeneity, and exceptional surface quality.

High-Pressure Die Casting also has the benefit of typically requiring little to no machining due to its exceptional dimensional precision and smooth surfaces. In comparison to other manufacturing techniques, high-pressure die casting is a productive, affordable method that:

- Create sturdy, lightweight components that require less machining than those that are produced.

- By forming delicate and complex shapes all at once, assembly and welding are not necessary.

- provide a wider variety of shapes than other methods for making metal.

- attains precise tolerances.

- High Pressure Die Casting Disadvantages

The main drawback of high pressure die casting is its porosity, but various methods like an evacuated chamber may be used to lessen this. Components produced by high pressure die casting typically cannot be thoroughly heat treated because of the existence of these pores (carrying trapped gases). Unfortunately, surface blisters would develop as a result of this.

According to your point of view, high start-up costs for high pressure die casting may not necessarily be a drawback. Despite having a higher initial tooling cost than alternative techniques, this process’s extended casting cycle also makes it possible to produce large quantities of goods at a low unit cost.

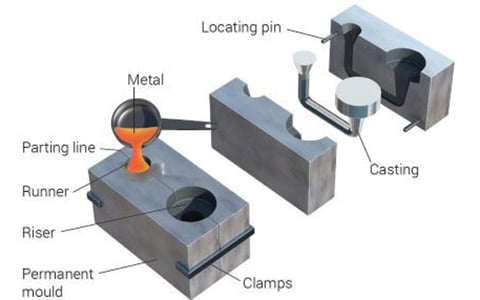

Gravity Die Casting

- What is Gravity Die Casting

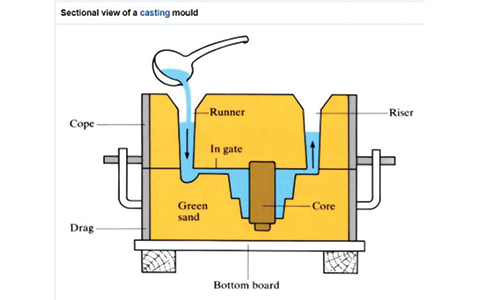

Gravity Die Casting is a permanent mold casting technique in which the molten metal is poured into the mold using a container or ladle. The only force acting on the mold cavity is gravity, and filling can be controlled by tilting the die. Sand cores can be used to include undercuts and cavities into component forms. Due to quick solidification, this method provides a superior surface polish than sand casting as well as improved mechanical qualities.

- Gravity Die Casting Process

Adding the molten metal using a ladle is a common manual step in gravity die casting. However, it is also possible to pour the molten metal using an automated ladle for some high-volume applications. By tilting the die, one may additionally regulate the filling’s speed and direction.

The casting process is substantially the same as sand casting, with the exception of how the molten metal is poured into the cavity of the die and the material used for gravity dies. There are four steps to it:

- A refractory coating is sprayed onto the heated die before it is sealed. The coating aids in the removal of the casting as well as in adjusting the temperature of the die during production.

- The metal is then manually poured into the die (a machine may also be used in some circumstances) and allowed to harden.

- The die is subsequently opened and the cast portions are either removed by hand or in some situations ejector pins are utilized on the mechanized machines.

- The casting is next cleaned of the junk, which includes the gate, runners, sprues, and flash (s). Before being shipped to the customer, the castings are further treated to eliminate any sharp edges and extra material.

- Gravity Die Casting Advantages

Producing dense, high-quality castings with superior mechanical properties like strength and stiffness is one of the benefits of tilting gravity die casting. Because of this, it is ideal for demanding automotive applications including suspension and brake systems. The primary benefits of gravity die casting technology include:

- suited for automated, high-volume production.

- A minimum investment is needed for the production of small and medium volumes.

- generates products that are suitable for heat treatment and have high mechanical qualities.

- Gravity die casting also allows for the production of pieces with intricate shapes since sand cores can be inserted into the mold.

- Gravity Die Casting Disadvantages

- Production rates for some alloys may be less than with high-pressure die casting.

- Compared to sand casting, the tooling costs are higher.

- Between 3 and 5 mm thick is the narrowest wall that can be constructed.

Vacuum Die Casting

- What is Vacuum Die Casting

Any traditional die-casting technique has a major problem with porosity. It seriously undermines the casting integrity, which lowers the quality and effectiveness. In order to minimize this, a vacuum system is used in the pressure die casting process. Vacuum die casting, or vacuum-assisted high pressure die casting, is the term used to describe it.

- Vacuum Die Casting Process

With the exception of producing a vacuum in the die chamber prior to casting, the entire vacuum casting process is similar to any other standard die casting method. Below is a step-by-step instruction sheet:

- Melt the metal you’ll need for casting first.

- Create a vacuum in the die cavity now by using the vacuum pump.

- The molten metal will then be injected into the cavity by applying pressure to it.

- Wait for the portion to cool and solidify after that.

- The portion should then be ejected from the die.

- Vacuum Die Casting Advantages

Manufacturers all over the world now favor vacuum die casting because it has some advantages. For instance:

- The vacuum casting procedure helps minimize surface flaws like blowholes and blisters.

- Vacuum die casting virtually eliminates the possibility of any casting porosity.

- The vacuum-induced negative pressure in the hollow allows the molten metal to quickly reach every crevice. As a result, you can cast parts that are thinner and more precise.

- Parts made of vacuum die casting are denser and have greater mechanical strength.

- Can also be used for plastic medical components made by casting abs plastic.

- Vacuum Die Casting Disadvantages

- Many intricate objects with many intricacies can be created using vacuum casting. Pressure forming is one example of a complex feature that necessitates additional tooling and is a challenge for this kind of manufacturing.

- This is something that is tied to the company that supplies the vacuum casting, and not the technique per se. The problem is that the mold utilized for the job needs to be cleaned frequently. If not, the resulting pieces will have signs of mark-offs.

- One of the most challenging problems that can arise but are unrelated to measurement is hollowness. Even the engineering and science that deal with this issue are still in their infancy.

Squeeze Die Casting

- What is Squeeze Die Casting

Because it combines the casting and forging processes, squeeze die casting presents itself as a variation of the conventional die casting technique. High pressure is used in squeeze die casting to solidify molten metals sandwiched between hydraulic press plates. Using pressure on the molten metals, near-net forms that are almost pore-free can be produced in super dense casting.

- Squeeze Die Casting Process

The tensile and mechanical qualities of alloys like zinc, aluminum, and some ferrous alloys are improved by the squeeze die casting process. The procedure starts with the addition of molten metal to the lower portion of the heated and lubricated die chamber, followed by the application of pressure before and after the solidification. Squeeze die casting uses less pressure than metal forging, which uses more pressure.

Along with the warmed die, an ejecting agent, such as graphite, is coated, and the assembly is placed on a hydraulic press. When the final product is totally in hard shape, it aids in its expulsion.

The upper half of the die is forced into the lower half of the casting as the metal begins to cool from its liquid, molten condition. The pressurization helps to ensure that the metal travels uniformly throughout the casting as it solidifies, which lowers the likelihood that the metal component will fail. The hydraulic press’s casting alloy is removed from the plates once the alloy has taken on a firm, solid form and the press ram has retracted.

- Squeeze Die Casting Advantages

- provides more shapes and parts than other manufacturing processes.

- After casting, little to no machining is necessary.

- Low porosity levels.

- excellent surface texture

- fine microstructures with components of greater strength.

- 100% material usage, no waste.

- Squeeze Die Casting Disadvantages

- Due to complicated tooling, costs are extremely expensive.

- Lack of flexibility due to tooling being devoted to particular components.

- Processes need to be precisely managed, which extends cycle times and raises costs.

- Substantial costs imply that in order to justify equipment investment, high production quantities are required.

Semi-solid Die Casting

- What is Semi-solid Die Casting

SSM commonly referred to as “semi-solid casting,” is a key new development in the method for producing high-quality metal castings from specific non-ferrous metals. Using this method, complicated items with near-net forms and excellent accuracy are primarily cast.

- Semi-solid Die Casting Process

Semi-solid casting material, which is 50% solid and 50% liquid, is used in the semi-solid die casting method rather than totally molten metal. The metal is melted at a temperature that preserves the semi-vicious state of the slurry. The metal maintains its 30% to 60% solid state at a temperature of up to 10 degrees Celsius.

The viscosity of the metal slurry might be 40% higher when the solid content is higher, which has an effect on the semi-solid die casting process. The dendrites in the metal are broken down by cooling, which increases the metal’s ductility.

As a metal freezes, dendrites, or tree-like crystal formations, form. Depending on the alloy being utilized, an appropriate semi-solid process is then used for the die casting. There are four widely used techniques for semi-solid metal die casting, including:

- Thixocasting

- Rheocasting

- Thixomolding

- Strain-Induced and Melt Activated Method (“SIMA”)

- Semi-solid Die Casting Advantages

All the advantages of die casting are available with semi-solid die casting, yet the majority, if not all, of its flaws and restrictions, including residual porosity, are also removed. Long-lasting qualities are one of the main advantages of semi-solid die casting.

- high-performance goods.

- increased effectiveness.

- Internally robust structures.

- Scalable methods.

- favorable to the environment.

- Semi-solid Die Casting Disadvantages

- The SSM casting method has a significant limitation with regard to temperature control.

- Compared to the standard die casting process, the equipment utilized in this method is more expensive.

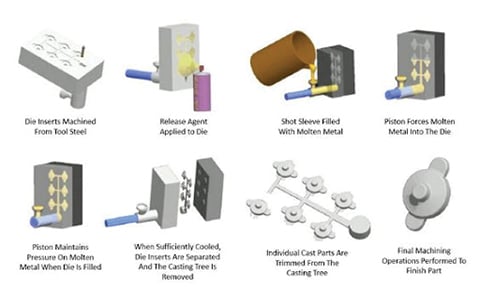

Complete Die Casting Process

- Preparation

The die itself must first be prepared before the gravity casting procedure can start. Basically, this entails heating it to an appropriate temperature and spraying a lubricant or refractory coating on it. This lubricant not only keeps the temperature of the die constant during production but also delays premature solidification and makes it easier to remove the cast after it has hardened. After that, high pressure can be used to tightly shut and clamp the die halves together.

- Injection

After this stage of preparation, a downward sprue is used to ladle molten metal into the die directly from a furnace. The technique makes use of gravity whether it is carried out manually or, in some cases, with the aid of an automated ladle. There are no additional pressures or forces imposed. Simply placed into the die from an upright, vertical posture, the molten liquid will naturally move down into the cast due to gravity.

- Cooling

The molten metal is then placed within the mold and allowed to cool and harden. Before the die is unclamped, the metal needs to have had enough time to fully set and take the shape of the mold. Premature cast removal can result in permanent flaws.

- Ejection

The die halves are unclamped, opened, and the cast portions are gently removed after a suitable amount of time has passed. The cast can be safely pushed out of the gravity die casting machine either by hand or, in some cases, using ejector pins.

- Trimming

Trimming is the last step in the gravity casting process. Any leftover metal from the casting, such as the gate, runners, sprues, and flash, is skillfully removed as the metal continues to cool. The surplus material and any sharp edges are removed with a variety of tools to produce the desired component shape.

Die Casting Advantages And Disadvantages

Die Casting Advantages

- Advanced Thin-walled Components

Aluminum die casting has an advantage over other metal molding castings and investment castings because it can produce intricately formed, lightweight components with high strength-to-weight ratios. The wall thickness of cast parts created using zinc can even be as thin as 0.3mm for parts made by die casting aluminum alloys.

- Superior Mechanical Characteristics

Die cast goods have superior mechanical qualities. The liquid metal appears fine, dense, and crystalline as it solidifies under intense pressure. Die cast pieces have a high degree of rigidity, hardness, and strength. They also offer higher durability and conductivity.

- Tolerance for High Dimensions

Die casting creates components with excellent dimensional precision and durability. Over time, the parts retain their dimensional correctness even when subjected to challenging circumstances. Die casting is therefore used to create intricate and internal machine parts that must meet high standards of precision and accuracy.

In comparison to other casting techniques, die casting maintains finer tolerances. In other words, there are few differences in the parts generated. According to GB/T 1800-2009, the usual tolerance class for die castings is IT13–IT15. Greater accuracy can be reached at IT10W 11. As a result, die casting’s outstanding dimensional precision reduces the requirement for machining and maximizes the use of the alloy.

- Fluent Surfaces

Die cast components have a crystalline surface that is uniformly smooth. The molten metal alloy is used in the die casting process to fill the molds and produce precise shapes. Therefore, the parts will be fine and smooth if the die is well-shaped and the process is in good working order.

Making glossy parts reduces the need for further post-processing steps, with the exception of unique requirements. Additionally, after die casting is complete, goods can be dispatched for delivery. This may shorten the length of the entire production cycle.

- Affordable for Mass Production

Die-cast parts frequently need less machining than other parts since the surface of die castings is frequently smooth and has great mechanical properties. Sometimes there is absolutely no machining. As a result, spending on auxiliary activities is reduced. Die casting’s ability to lower post-processing costs contributes to its cost-effectiveness.

Die Casting Disadvantages

- Simple to Produce Porosity

Molten metal pours into the mold cavity of the die casting process at a high rate of speed, yet the cavities are not gas permeable. As a result, gas bubbles that compromise the structural integrity of manufactured parts frequently become trapped within castings.

Die castings with gas cavities would not perform as well when subjected to extreme conditions, such as heat treatment for hardening. Such items are also more prone to machining challenges. As a result, the parts’ machining allowance should be kept to a minimum. If not, the die casting surfaces’ hardened layer would be scraped off, revealing the surface.

- Support Non-ferrous Metals Typically

In general, non-ferrous metals having lower melting points than ferrous metal alloys are ideal for die casting. Iron and steel alloys are supported by the process, nevertheless. Ferrous metals’ low corrosion resistance and extremely high melting temperatures result in short die lives. As a result, non-ferrous metal alloys are the only ones that manufacturers pick for die casting.

Additionally, casting ferrous metals involves a great deal of intricacy and a number of unanticipated difficulties. Because of this, businesses only use non-ferrous metals for die casting.

- Unsuitable for Low Volume Manufacturing

Due to the high cost of maintenance and tooling for die casting equipment, die casting is not a viable option for low-volume production. As a result, the procedure is expensive and appears difficult for small-scale production. However, as costs are evenly divided across the numerous goods produced, large-scale production becomes economically viable.

- Low Die Rate

Steel dies’ efficacy is compromised by metals and alloys with high melting points. To withstand thermal deformation, certain metals, like copper, must meet stringent standards. Alloys with high melting points continue to be present, placing stress on the molding die and lowering its durability.

- Large Capital Expenditure

Die casting requires expensive machinery, dies, and additional accessories, in contrast to other casting techniques. Die casting is impossible to perform without the necessary tools. Zinc is an inexpensive resource that is employed to reduce expenses, although the cost of production as a whole remains high. Die casting is only economically viable in high-volume manufacture.

Die Casting Applications

Die casting is typically used for mass production or the casting of several identical components. High casting quality is obtained despite the use of high pressure in the production process. Die casting is a technology that is best suited for producing lightweight components that are very thin (up to 1 mm).

Die cast parts are most frequently produced for the automobile sector, including wheels, blocks, cylinder heads, valve blocks, and manifolds. Approximately 84 percent of the castings made by German foundries are for this industry.

Because aluminum components are used, the weight of the vehicles is reduced, which lowers fuel consumption. Additionally, die cast parts are employed in the following sectors:

- Lighting Technology

- Power Tools

- Machinery

- Aerospace

- Domestic Appliances

- Electronics

- Furniture

Foundries will be interested in other industries like electromobility in the future. Castings of light metal have a tonne of possibilities because of this.

What Are The Most Common Metals Used in Die Casting

Aluminum

Due to its propensity for cracking or shrinking at high temperatures, aluminum is frequently alloyed with silicon or copper when used in die-casting. Aluminum’s hardness and fluidity are significantly increased when combined with these metals.

Aluminum is utilized to make components with thin walls and complex shapes because of its great dimensional stability. Aluminum is advantageous in components that will be exposed to thermal or electrical energy because of its resistance to corrosion.

Copper

Die-casting also frequently uses alloys based on copper. Since several of these alloys are highly robust, mechanical items can benefit from their use. Because of its extremely strong corrosion resistance, copper is frequently utilized to make plumbing and electrical components.

Zinc

Due to its great strength at room temperature, zinc die casting is a very simple process, although it can be alloyed with aluminum to further enhance these attributes. Zinc is appropriate for hot-chamber casting because it has a lower melting point than aluminum. Additionally, it is useful in the production of items like connectors and gears that need to be strong and precise.

Magnesium

Magnesium is a good material for die-casting operations that call for thin-structured walls and fine accuracy since it has a high strength-to-weight ratio despite being a relatively light alloy.

Conclusion

Using reusable metal dies, die casting is an extremely efficient manufacturing process for producing items with precise dimensions and clear definition in huge quantities. Contact our SeaSkyMedical Platform to learn more about supplier capabilities or to find more particular die casting services in order to seek suitable sources for die casting services or bespoke die creation.