SeaskyMedical, one of the top medical consumable manufacturers, is dedicated to providing top-notch medical solutions through its best medical consumables and disposables.

We constantly expand our medical plastic injection molding capabilities, and high-speed German injection molding machines are equipped in our ISO 8 clean room. The fine screw of our injection molding machine can be accurately measured to 0.02g, clean room molding is also beneficial for the production of transparent items for medical use.

Our experts are equipped to handle the design of different medical consumable items as per the industry standards of safety and carry out medical device product development according to strict medical standard.

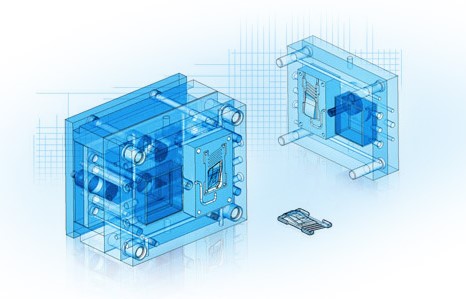

Plastic medical consumables require mass production without deviation from standard designs. We provide free precise mold tool designs when it comes to medical plastic injection design.

The production process of medical disposable begins with injection mold material selection. We choose the right plastic materials from chromatography resins and columns. Biocompatibility is also being considered.

The computerized production process is capable of handling even the tiniest variations in requests. We use CNC machining to handle big bulk medical supplies and maintain uniformity. This allows for precision manufacturing at different levels of production.

With each client order, various molding methods like micro molding, insert molding are operating at peak efficiency. The cleanroom here ensures sanitary production and reduces the risk of contamination throughout the production process

A number of secondary operations with injection molding are offered here. With our contract medical device manufacturing, clients also get the options of choosing from different secondary operations. You can opt for along with manufacturing and assembly.

We can serve the medical business on a variety of accounts involving consumable materials. Our team manufactures china medical disposables using a variety of injection molding techniques. Overmolding, insert molding, and micro injection molding are among the services provided here.

The medical consumable items from SeaSky Medical are made with utmost care for quality at every step during the production process. Our products are manufactured with proper quality control procedures.

Our services ensure that the production is done away from any external sources of contamination. One can rely on our experts to protect the products functionality from any harmful contaminants.

Injection molding for medical services relies on uniformity. We achieve it through a streamlined process which enables us to present high tolerance. This causes little deviation in design and helps manufacture standard sizes.

We not only provide a quick response, but also offer high production capability for bulk orders to the clients. With the assistance of 10 injection molding machines equipped with the latest technology, the best medical consumables are created by the experts.

The functioning and applicability of medical consumables and medical disposables are the foundations of our designs. For mass manufacturing, we may adjust the sizes and give a wide size range as per the client’s needs.

Our team of experts specialize in quality control, both inside and outside the cleanroom. All types of medical supplies by SeaSky Medical will be of optimal quality and ready to be used in a sterile environment.

Micro medical disposables are manufactured with size requirements that go into microns. Our micro products fall in the range of 0.1g to 0.5g, as the team caters to the top medical disposable companies.

SeaSky Medical has been in the field of manufacturing medical consumables and disposables for more than a decade. We understand the trends and requirements of the industry and make sure their facilities are always ready to help the clients out.

Selecting the right material for injection molding is important because the tolerance, performance, and strength depend on it. We work with medical-grade materials and operate as bulk medical supplies.

When it comes to plastics used in medical devices, professional medical disposables manufacturers are the best bet for any kind of order. Whether it is assembly, molding, quality or hygiene, our team members are trained enough to handle it all.

The medical micro molding process is conducted in perfect manufacturing conditions to prevent any kind of interference. We have an ISO 8 cleanroom and take quality control very seriously during the streamlining process.

We’ve reached out to ten companies who can supply us with raw materials for unique solutions. All hospital disposable items we manufacture are medical-grade and safe to use, thanks to the ISO10993 biocompatibility with various resins and columns.

SeaSkyMedical has invested in specialization services that cater to a wide variety of clients across the medical industry. Our medical molding machines are sourced from Japan and Germany to give precise measurements.

We offer various molding methods. Medical injections must be formed with extreme precision. Industry and application are considered by professional disposable medical supplies companies while verifying and validating medical devices.

We will always offer you a cost-effective pricing plan. You will only have to pay for what you receive. Seaskymedical is thus a one-stop destination for clinic supplies and medical disposables.

Understanding the need to ask for customized solutions as per the application of different hospital disposable products, we fall into the list of hospital consumables suppliers who are willing to offer you with customized solutions.

SeaSkyMedical has mastered the process of streamlining its products. Our healthcare consumables are manufactured within the stipulated time decided by the client, with the facilities supporting efficient production.

Once you come to us with your order, the team initiates the work instantly. Therefore, our order processing time is shortened in order to provide the clients with nothing but the best medical consumable items available in the hospital.

Check through our cases and see how we solve problems with robust injection molding capabilities.

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.