The automotive industry is constantly changing, as automakers seek innovative techniques to make high-quality, affordable, and eco-friendly vehicles. One of the latest trends in auto manufacturing is using plastic injection molding to produce various plastic parts and components. This article will examine why automotive plastic injection molding is becoming more popular, the materials used, different molding techniques, and how manufacturing processes are used in the auto industry. We will also explore emerging trends and innovations in automotive injection molding.

Why use plastic parts in the automotive industry?

Plastic is used more and more in cars today. About 20% of automotive Components are now plastic. There are a few main reasons for this:

- Weight reduction: Plastic parts weigh up to 50% less than metal parts. By replacing some metal with plastic, cars can weigh half as much. Lighter cars need less fuel and put less stress on the engine and brakes. They also tend to last longer.

- Cost savings: Plastic material and plastic injection molding are more affordable than metal and fabrication. Car companies can save money on both parts and manufacturing.

- Design flexibility: Injection molding can produce complicated shapes that are hard to make with metal. This gives car companies more options for innovative part designs and improving vehicle styling.

- Durability: Plastic parts resist damage, wear, and corrosion better than metal. They tend to last longer without breaking down or needing repair. This means fewer cars in landfills and repair shops.

Plastic parts may only make up 10% of a car’s weight but can cut total weight nearly in half. They deliver significant improvements in sustainability, affordability, and performance. It’s easy to see why plastics have become so important for modern automotive engineering and design. By replacing more metal components with high-tech plastics, cars of the future will be even lighter, cheaper, more advanced, and environmentally friendly.

Plastics help enable the key trends shaping the auto industry like fuel efficiency, cost reduction, design innovation, and sustainability. For these reasons, plastics and injection molding will likely play an even greater role in vehicle manufacturing going forward.

Key Benefits of Using Automotive Plastic Injection Molding in Auto Manufacturing

Injection molding provides many benefits to automotive manufacturers:

- High precision, tight tolerances, and high-quality surface finishes.

- Many plastic and finish options for different needs.

- Nearly identical, repeatable parts. •Fast, low-cost prototyping. •Very cost-effective mass production.

- Integrated color matching without painting.

The initial investment in molds pays off through efficient, low-cost production of high-quality parts. Although molds are pricey upfront, high-volume production lowers the cost per part over time.

Injection molding gives car companies an ideal manufacturing process for affordable, durable, and stylish components that meet their strict standards. By leveraging the variety of plastics, finishes, and techniques available, automakers can utilize injection molding throughout vehicle design.

Injection molding automotive parts provide an economical way to improve quality, reduce weight, increase design options, and build in more technology. Injection molding will likely play an even bigger role in producing the higher-performing, more fuel-efficient, and connected cars of the future.

Materials Employed in the Manufacturing of Injection Molded Automotive Products

Automotive plastic injection molding companies use various plastic materials to create a wide range of automotive parts and components. The commonly utilized material selection in plastic injection molding is primarily polypropylene, polyurethane, and PVC, also known as The Big Three.

| Material | Features | Percentage Of Chosen in a Car *Based on Seaskymedical Historical Data |

| Polypropylene (PP) | The most regularly used plastic in the automobile industry. It features remarkable resistance to heat, chemicals, and impact, making it ideal for use in automobile bumpers, electrical housings, and scuff plates. | 32% |

| Polyurethane (PU) | Ideal for products requiring a high degree of flexibility, such as foam seats and suspension bushings, polyurethane is also used to create seals, gaskets, and insulation panels in automobiles | 17% |

| Polyvinyl Chloride (PVC) | Flexible and heat-resistant, PVC is used to manufacture both hard and soft automotive parts, including interior panels and dashboard components | 16% |

The Various Injection Molding Techniques for Manufacturing Automotive Parts

There are three main injection molding techniques used in the automotive injection molding process:

- Thermoplastic molding: Fast, low-cost, high-volume production of many different parts. Uses plastics like polypropylene, nylon, and ABS.

- Elastomeric molding: For flexible, shock-absorbing parts that need vibration damping. Uses rubber and silicone.

- Thermosetting molding: For precise, dimensionally accurate parts. Uses plastics like epoxy and polyester that harden during molding.

These techniques provide an ideal process for making affordable, durable, and high-performing plastic components to meet the needs of any automotive application. By leveraging all three methods, automotive manufacturers have tremendous flexibility in how they design, develop and manufacture vehicles using plastics. Injection molding will continue enabling progress in vehicle efficiency, quality, technology, and cost.

Uses of Plastic Injection Molding in Automotive Manufacturing

Injection molding produces a wide range of plastic pieces and parts for the automotive industry. These can be broadly grouped into three main areas: exterior vehicle parts, interior components, and under-the-hood parts.

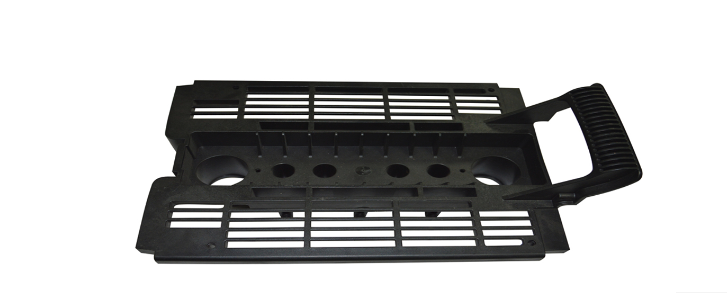

Exterior Automotive Parts

Injection molding is used to manufacture many aesthetic exterior components of cars, including front grilles, bumpers, step bumpers, headlights, fenders, side mirrors, door panels, and splash guards. These exterior components are typically made from durable and weather-resistant plastic materials to ensure longevity and performance.

Interior Car Parts

The automotive interior is another area where automotive plastic injection molding plays a significant role. Automotive parts such as roof linings, dashboards, door handles, center consoles, and dashboard compartments are all examples of injection molded products. Furthermore, decorative automotive moldings in luxury cars are also often produced using this manufacturing technique.

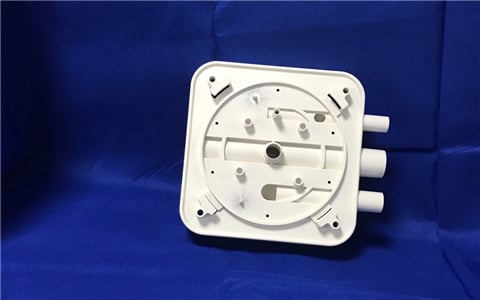

Under-the-Hood Components

Traditionally, engine components and other parts under the hood were mostly made of metal. However, as injection molding has improved and becomes more widely used, manufacturers have increasingly turned to plastics for these parts. Some under-the-hood components now made with injection molding include sensors, cylinder head covers, oil pans, and electrical kits.

Future Trends and Innovations

Plastics have made cars so much better in many ways. They help cars perform better, have stronger and safer structures, and get much better gas mileage. By making cars lighter, plastics allow them to use less fuel and produce fewer emissions. Because plastics are so useful for automakers and the environment, the market for plastics used in cars has become huge.

The plastics market for the automotive industry was valued at nearly $24 billion globally in 2016. Demand for plastics in the auto sector is forecast to grow $50 billion by 2024.

The future of automotive injection molding is geared toward more sustainable, smarter, and efficient manufacturing. New materials and technologies will drive progress in producing affordable, lightweight, and connected cars. Automakers can leverage these trends to build the vehicles of tomorrow and a greener future of transportation.

- More sustainable plastics. As concern for the environment grows, car companies want plastics that are more eco-friendly. They are looking at bio-plastics from plants and recycled plastics. Using sustainable materials will lower the impact of vehicle manufacturing on the planet.

- Advancing plastics technology. New high-tech plastics are always being created. These plastics are lighter, stronger, and more durable. They allow injection molded parts that improve vehicle performance, gas mileage, and safety. Progress in plastics will drive more innovation in automotive design and engineering.

- Smart, connected parts. The injection molded parts with built-in sensors and electronics will enable smarter, connected cars. Smart parts can help improve vehicle automation, monitoring, diagnostics, and more. They represent the future of advanced automotive manufacturing.

- 3D printing and additive manufacturing. Technologies like 3D printing are transforming injection molding. They allow for faster prototyping of new parts before mass production tooling is made. 3D printing also enables a new mold design that was previously too complex to produce. These technologies will make automotive injection molding even more efficient and innovative.

The future of automotive injection molding is geared toward more sustainable, smarter, and efficient manufacturing. New materials and technologies will drive progress in producing affordable, lightweight, and connected cars. Automakers can leverage these trends to build the vehicles of tomorrow and a greener future of transportation.

Conclusion

Plastics have revolutionized the automotive industry with their versatility and durability. Automotive manufacturers have found that plastic material is a superior alternative to metals in many automotive applications. Plastic parts last longer and cost less.

Seaskymedical specializes in creating high-quality engine components through injection molding. We handle the entire manufacturing process from prototyping to production. Our plastics experts can help you mold design and develop plastic auto parts to suit your needs.

If you’re looking for affordable injection molding services for your next automotive project, contact Seaskymedical. We have the experience and capability to produce plastic parts at any volume. Discover how plastics can transform your vehicle designs.