In the medical industry, product quality cannot be compromised because it greatly affects medical safety. SeaskyMedical strictly follows ISO 13485:2016 quality management system and is certified by the third-party.

We cooperate with more than 10 large raw material companies. Our raw materials come from the original factory, and we can provide a COC factory certificate. ISO10993 biocompatibility report is also available as customer request. In addition, we purchase color masterbatches that have passed medical certification from reliable suppliers for a long time.

…

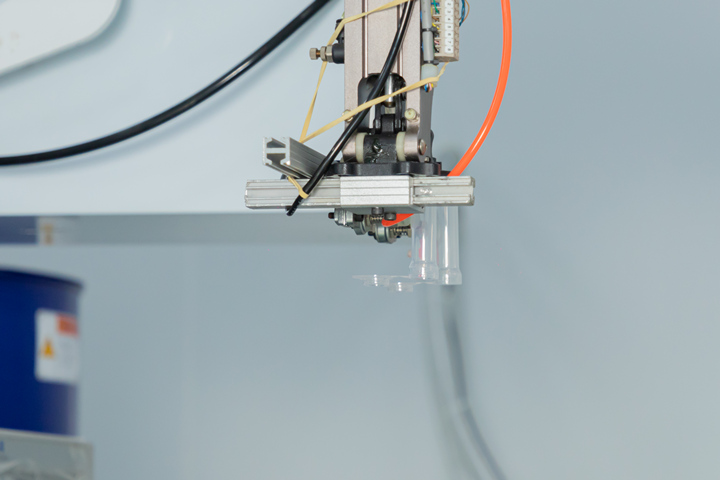

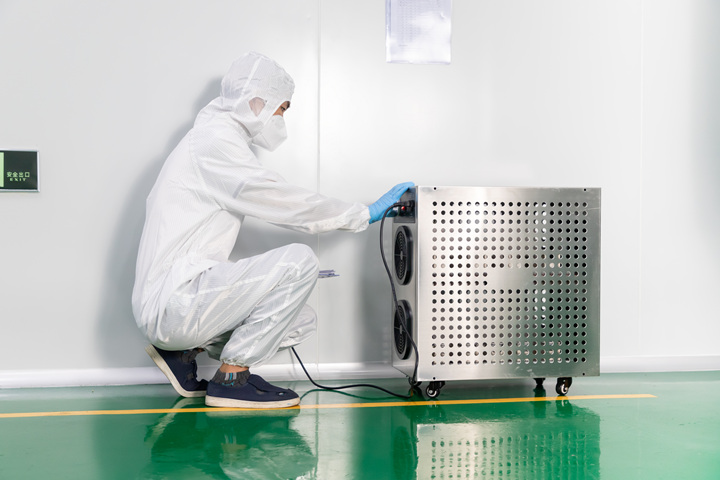

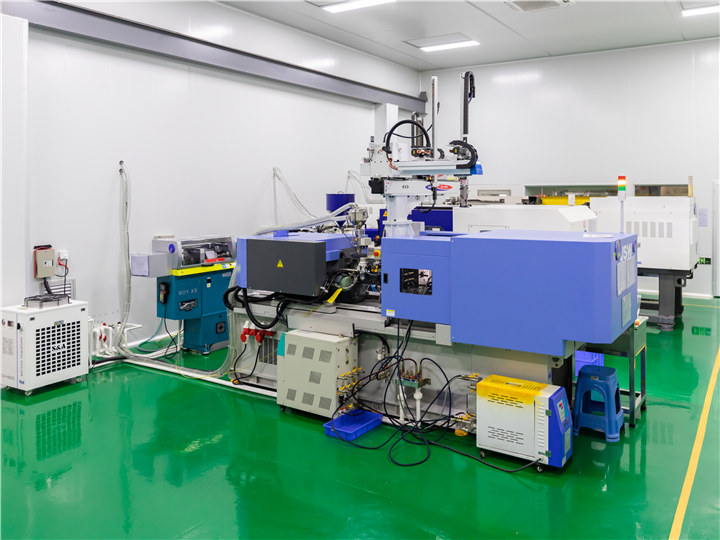

Dust-free manufacturing can reduce the environmental impact on products and improve product quality. Therefore, to maintain our cleanroom condition, we separate the material feeding and injection. Also, we apply automated equipment such as robotic arms, reducing personnel contact. Apart from that, we conduct daily disinfection for the cleanroom, as well as test and record the cleanliness twice a day.

SeaskyMedical is equipped with imported precision processing equipment and high-precision injection molding machines, such as Japan FANUC and Germany BOY. To ensure product quality and punctual delivery, we upgrade our equipment every 3-5 years.

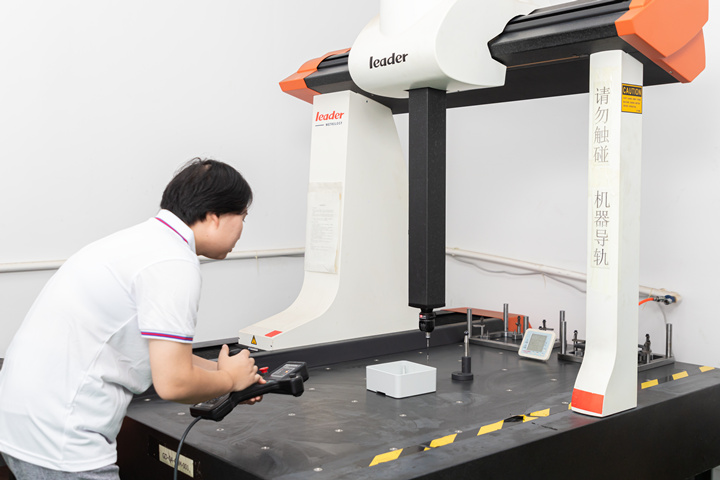

The medical field has a very high demand for product accuracy. Our workshops are equipped with advanced measuring instruments, such as a caliper, 10x-20x magnifier, 2.5D Vision Measuring Machine and Coordinate Measuring Machine. Utilizing these modern instruments, our inspectors control our product accuracy, meeting your tolerance requirements.

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.