Medical consumables are an essential part of patient therapy and diagnosis. These are instruments used in the medical field for testing and treatment. It is not widely discussed, but it is an essential part of our daily lives.

These consumable products are used by healthcare professionals and patients alike and can be found in various places, including operating rooms, wards, clinics, and even at home. There are a number of different types of consumable products, each with its specified use.

With all of the different types of consumable products out there, it can be challenging to understand what they’re used for. It is essential to learn and understand which products are used to help save lives every day.

In this article, we’ll go over the medical supplies you’ll need. Also, explain the application of medical injection molding in medical supplies.

What Are Medical Consumables?

Medical consumables are items used by doctors and nurses to treat patients. Consumables include medications, bandages, and other supplies. Medical consumables are available in a variety of forms, each with its own set of benefits and drawbacks.

Consumables like oxygen tanks, for example, can be pretty expensive. Others, such as disposable gloves, are inexpensive but short-lived. It is critical to choose the right medical consumable for any given situation.

The List of Medical Consumables

1. Anesthesia

This is the process of temporarily putting someone to sleep in order to perform surgery or medical treatments on them. The procedure is carried out using anesthesia machines and breathed gases.

In addition to the anesthetic, the following items will be required for the procedure:

- Masks

- Epidural Kits

- Breathing Circuits

- LMA’s

- Hyperinflation Bag

2. Drainage/Irrigation

This treatment is performed to drain the patient’s chest of excess fluids and/or air. Drainage is a technique that is frequently used to treat pneumonia and tuberculosis. Irrigation is the process of using fluids to clean the lungs’ airways in patients who are experiencing respiratory distress.

Additional includes for this procedure are the following:

- Irrigation Trays

- Suctioning Catheters

- Yankauers

- Wound Evacuators

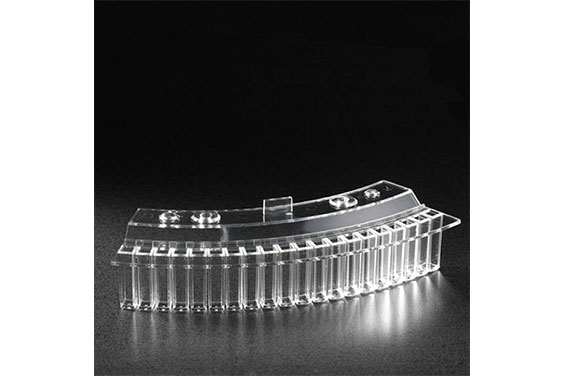

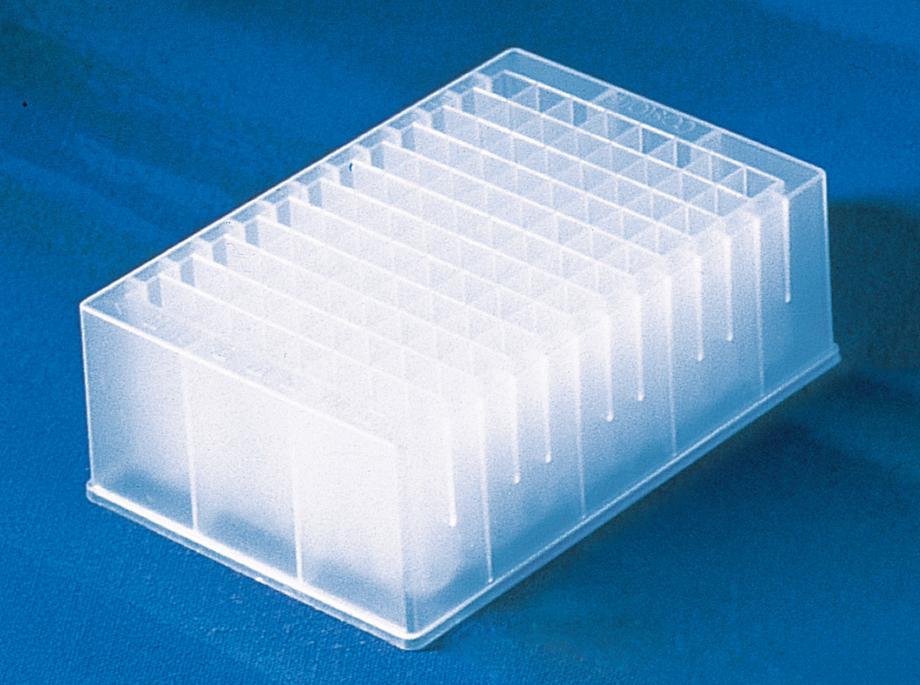

3. IVD (In-vitro Diagnostics) Procedures

In-vitro diagnostics (IVDs) are tests that can tell if someone has a disease, a condition, or an infection. In vitro means “in glass,” which means that these tests are usually done in test tubes and other equipment instead of in vivo tests done inside the body. They may be done at a lab or a doctor’s office, but they can also be done at home. The tests can be done on a wide range of instruments, from small, handheld tests to complex lab instruments. They make it easier for doctors to diagnose patients and find the right treatments for them.

Things needed for this procedure:

- Microtainers

- IV Bags

- Disposable sampling tube

- 96 Deep well plate

- Electroporation cuvettes

- Rapid antigen test

4. Common Surgery

This is a reference to the act of surgery. ‘On a routine basis, wounds are treated, cysts are removed, and other treatments are performed.’ these are common surgery.

The list of Surgical Consumables for common surgeries includes:

- Scalpel

- Scissors

- Forceps

- Clamps

- Needles & Suture

- Retractors

- Suction

- Staplers and Clips

- Energy Systems

- Laparoscopic Instruments

5. General-Purpose Procedures

This is a term that refers to the daily activities that take place in a medical facility. This is distinct from the more time-sensitive therapy delivered during a medical emergency. This refers to general procedures performed by medical professionals on their patients. This can include sutures, sigmoidoscopy, injections, and many others.

The list of medical consumables for general-purpose procedures includes:

- Bandages

- Gauze

- Syringes

- Tape

- Staples

- Stethoscopes

- Medical Scales

- Surgical Blades

- Surgical Tools

- Tourniquets

- Injection Needles

- Medical laboratory supply

6. Diabetic Procedures

A competent medical specialist performs this procedure to aid in identifying blood disorders such as anemia and screening for prospective illnesses. The two most important tools in this procedure are a blood glucose meter and a lancet. They take blood samples from the patient and send them to the lab for further testing.

Consumables needed for a Diabetic Procedure:

- Blood glucose meter

- Blood sample test strip

- Blood lancet

- Blood syringe

- Diabetic wearable device

7. I.V. Start

This is the site of catheter insertion into the patient’s vascular system. The drip chamber is filled with 200-400 mL of crystalloid solution, and the drip chamber bag is suspended above the patient’s bed during intravenous start-up. The catheter’s tubing is then put into one of the patient’s veins, allowing for a predetermined fluid delivery rate.

Consumables needed for I.V. Start procedure:

- IV infusion set

- Catheter Set

- Hospital Tray

- Solution Container

- Bag of Crystalloid Solution to be administered

- Monitor Set

- Electrode

8. Dental

Dental procedures are able to treat a wide range of dental diseases and disorders. This includes the removal of tooth decay, damage, and infection. They are performed by dentists in dental offices, dental clinics, and in dental hospitals. Some dental procedures are simple, while others are complex. Dentists conduct oral examinations and execute procedures such as fillings, implants, and tooth extractions on patients.

Consumables needed in a dental clinic:

- Tooth whitening trays

- Dental hygiene kits

- Dental floss

- Adhesive for the removal of the old filling

- Set for the removal of the old filling (drill, clamps, and others)

- Plastic foil

- Chemical cleaner

- Needle holder

- Undiluted disinfectant

- Dental chair accessories

9. Burns & Blisters

This occurs when your skin has sustained significant injury. This can be a first- to third-degree burn. First-degree burns are the least severe. They are sometimes referred to as “superficial” burns due to the fact that they only affect the outermost layers of your skin. On the other hand, third-degree burns can severely disfigure and even kill a patient. The most critical part of treating burns and blisters is prompt treatment.

Consumables needed for Burns & Blisters treatment:

- Alginate dressing

- Aluminum adhesive dressing pad

- Burn to dress

- Cotton pledget

- Electrolyte jelly

- Hydrocolloid gauze

- Hydrogel dressing

- Non-adherent dressing

- Polyurethane foams

- Silicone adhesive dressing

- Surgical dressing

- Telfa dressing

- Thermal burns dressing

- Bandages

- Skin Adhesives

- Cleansers

Trusted Molding Manufacturer of Medical Consumables – Seaskymedical

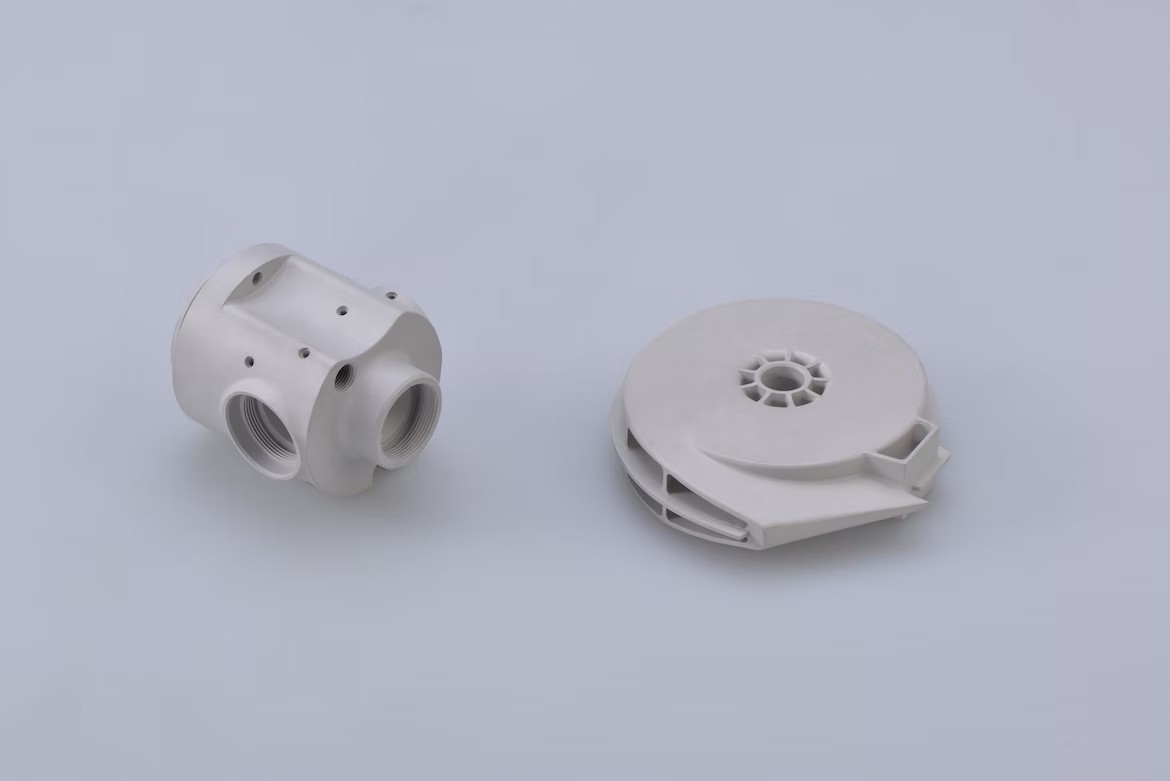

Many medical consumables are made from medical-grade plastics such as polyethylene, polypropylene, silicone rubber, etc. These materials are biocompatible and do not produce adverse reactions with the human body. During the injection molding process, to ensure the sterility and quality of medical consumables, cleanroom injection molding is chosen. This type of medical injection molding technology is generally conducted in a “cleanroom” or “dust-free room”. The air quality, temperature, and humidity in this environment are strictly controlled to minimize the risk of contamination.

Seaskymedical is one of the leading medical injection molding factories. They can manage all of the difficulties of producing a plastic medical device and its casings, delivering high production efficiency and high-volume repeatability to their valued customers and business partners.

Their advanced injection machines are used to produce all cutsom components of medical consumables from around the country. Medical overmolding and micro injection molding are two services that can be utilized to manufacture medical components that Seaskymedical is a master at.

Capabilities in Manufacturing Medical Consumables

Product Development

The professionals at SeaskyMedical have years of experience designing and creating medical plastic products and precision molds. They begin by analyzing your product in-depth and conducting DFM research.

They minimize project risks by recommending optimum materials, optimizing your product design, and successfully arranging the injection molding process using DFM analysis. Contact SeaskyMedical early in the development of your product for a dependable solution.

CNC Plastic Machining

CNC (computer numerical controlled) machining uses high-speed cutting tools to make designs on metals and plastics. One of CNC plastic machining advantages is dealing with various materials, including mild and stainless steel, magnesium, titanium, and even highly engineered polymers and carbon fiber.

Manufacturers must have several distinct manufacturing processes to meet the demands of their clients, which SeaskyMedical is proud to be in the business, so they maintain the most up-to-date processes and equipment and train certified personnel to ensure that our products are on-time, on budget, and of the highest quality.

Medical Device Contract Manufacturing

This is the procedure by which a sole proprietorship in the medical technology industry outsources manufacturing to another medical device manufacturer. Healthcare contract manufacturing is conducted by OEM specifications, as well as ISO:13485 and FDA regulations.

Seasky Medical is a well-known contract manufacturer of medical devices with years of experience. We differentiate ourselves from other contract medical manufacturing firms through our process efficiency and high-quality output. We make a point of keeping our clients informed of the project’s development and soliciting their comments.

Medical Device Assembly

The expansion of the healthcare industry has resulted in the production of assembled medical equipment. Making these gadgets may take a considerable amount of time and effort. Additionally, it must be carried out in a sterile and contamination-free environment, necessitating the search for reputable medical device assembly businesses.

We excel at this work as a medical molding manufacturer with over ten years of experience in cleanroom medical device assembly. We adhere to product and regulatory criteria to ensure that medical devices are created safely and adequately. Additionally, we carry out this responsibility in our Class 7 and Class 8 clean rooms, free of pollution and toxins, guaranteeing that medical devices remain clean and sanitary.

Free Mold Design Service for Medical Devices & Consumables

Mold design is crucial for making high-quality, practical medical equipment, and it can only be done with the highest care and precision. When creating a bespoke mold and design for a client, the injection mold designer must comply with medical standards.

By designing injection molding tools precisely, the process of streamlining is quickened. Additionally, it cuts expenses, streamlines daily operations, and positively affects product quality. Seaskymedical provides FREE mold tool design services and injection molding options that are state-of-the-art in technology.

To Sum it up,

Medical molded consumables are commonly disregarded since most people do not consider them. They are rarely discussed in cinema or literature, yet they are utilized daily in hospitals worldwide. Medical consumables are typically used with hospital medical devices and are necessary for most treatments and research.

Molding consumables are essential for the functioning of medical facilities, diagnostic procedures, and routine maintenance. Numerous contemporary therapies would be impossible to perform without medical consumables.

At Seaskymedical, one of the professional medical molding manufacturers, we provide an array of customized medical molding of medical consumables, from IV infusion set to plastic dental instruments. We pride ourselves on producing items that are safe and of excellent quality.

If you require high-quality medical equipment to expand your medical facility or to help your business grow. Contact us today! But as a supplier of high-quality medical consumables and disposables, there are no medical consumables in stock, we only start manufacturing when you send the specifications of your medical molded products, which will guarantee the quality of medical consumables.