The insert molding process is one that helps to modify appliances into better shapes and designs for easy and convenient consumer use. In fact, a lot of appliances we see around have gone through this process.

The insert molding process involves the formation of plastic parts around several non-plastic objects. Products made through this process can be as simple as kitchen utensils, and it can also be as complex as auto parts/accessories.

This article contains the necessary information needed on the insert molding process, its application, its benefit, and the defect that may occur during the course of production.

What is Insert Injection Molding

Insert injection molding is a process where two different components are combined to create a more enhanced object for consumer use. The primary component (insert) could be iron, copper, steel, glass e.t.c. The insert injection molding process thereby ensures that the primary component is completely locked into the secondary component (plastic resin) through the use of mold and molten plastic.

Most products that pass through the insert molding process tend to be much more durable and strong. One of the major reasons why this process has been adopted is because it gives producers the chance to customize their products into whichever form they deem fit.

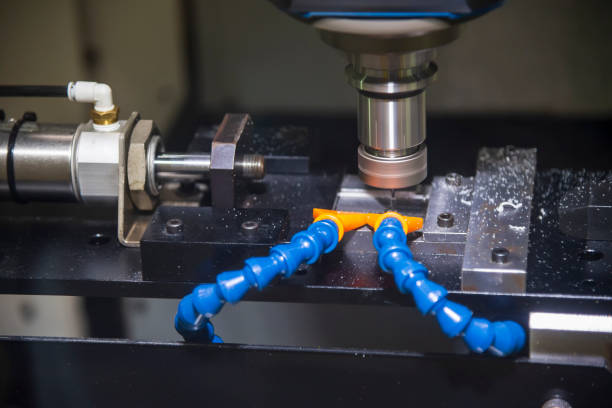

Insert Molding Process

The insert molding process requires a lot of scrutiny on the part of the mold engineer because a little mistake in the mold could jeopardize the whole process.

- The first thing to do is to carefully fabricate the required mold to properly hold the insert and withstand high temperatures.

- Plastics are then heated at a high temperature until they attain a liquid state.

- When this is done, the molten plastic is injected into the mold under high pressure so that it can reach all parts of the mold and also remove air through the vent.

- Finally, the mold is removed a normal room temperature, while the plastic gets to solidify around the insert.

Benefits of Using Insert Molding Process

- Serves as insulator: Electrical cables are made up of copper which are conductors that transmit power. When two connected copper wires meet, there will be a break in power transmission. To avoid this, the insert molding process is adopted to halt the flow of electrical current.

- Increase durability: Objects quoted with plastic tend to be more durable because plastic is resistant to rust and does not decay. The insert molding process thereby helps prevent metal from rusting even when it is exposed to direct sunlight.

- Reduced weight: Objects made from plastic can be about 50% lighter than those made from metal. Therefore, using plastic quotes as a substitute for metal will help reduce the weight of an object to a reasonable level.

- Custom Designs: Compared to iron, plastics can be easily transformed into several shapes, designs, and patterns. This has made manufacturers adopt the use of the custom plastic injection molding machine to customize products in ways that will be useful to consumers and also create a form of trademark for its brand.

Materials Used in Insert Molding Process

Before commencing the insert Molding process, there are three basic materials that must be combined together in order to come about a perfect product. They are; Mold, Insert, and plastic. Below are the plastic types suitable for the job.

- Thermoplastic: This is the best plastic for molding because it is eco-friendly and objects made out of it can easily be recycled. This plastic ensures variance and sheen in the molding process and they are highly resistant to chemicals. Examples include; Nylon, Polystyrene, Polyethylene etc.

- Thermoset : This is a type of plastic that is quite similar to thermoplastic but can not be further recycled due to the presence of some irreversible chemical bound. E.g Epoxy and Phenolic.

Application of Insert Molding Process

Due to the numerous benefits derived from insert molding, manufacturers across various sectors are constantly applying it to give their products the best look and value. Below are some of the sectors it can be applied to.

- Medical Device Part Manufacturing

The medical sector is a key stakeholder when it comes to the use of insert molding. This is because medical injection moldersare able to make use of plastic to reduce the weight of life support and surgical tools, giving them a shape that will improve efficiency.

Equipment with medical injection molding parts includes: Oxygen masks, Dental X Ray tools, Lab housing, and casing tools, Surgical implements, Test tubes e.t.c.

- Electronic parts

One of the major reasons why insert molding is applied on electrical parts is because they serve as an insulator. Without the appropriate insert molding, there will be constant break/destruction of power transmissions. Examples of this application include: cables, screw drivers, knots and bolts, wall sockets, e.t.c.

- Automobile Parts

Back in time, most vehicle parts were made up of metal which made them very heavy and clunky. With due research and the advent of insert molding solutions, manufacturers were, therefore, able to reduce vehicle weight drastically.

- Building and Construction Tools

The building sector is not left out either because they also push towards having a durable, stable, and lightweight product for production. Starting from materials used for plumbing down to trowels and spades, they are all products of the injection molding process.

Considerations Before Insert Molding

- The first thing to consider before commencing insert molding is Mold Engineering. The type of product you are willing to produce will determine the shape, structure, and size of the mold needed. The mold must be calved under serious supervision as a little defect could result in wastage.

- Another thing to consider is the type of resin suitable for whichever product is to be made. According to the product area of use, different resin types are required for optimum results.

- Also, the injection process should be considered and this process can either be done manually or mechanically. Products created manually tend to be cost efficient while the mechanically process is more efficient and can produce much product per hour.

Concerns During Insert Molding Process

Most insert molding concerns still fall back on mold engineering. The mold must be designed in such a way that will be able to give the insert enough grip and grit as a change in its location can spoil the whole process. The insert must also be able to withstand the high temperature that comes along with the production process.

Sinking is another concern caused by a result of shrinkage. They occur when the plastic is not cooled enough before separation from the mold or due to insufficient pressure in the mold cavity.

Possible Defects during Insert Molding Process

- Wraps: Wraps are the bends, twists, and uneven patterns that were not initially part of the design. This occurs when a separate part of the mold cools at different times. To avoid this, the mold must be designed to have a uniform wall thickness and the plastics selected must be new (unrecycled).

- Voids: This happens when bubbles or air pockets are trapped within a part. It can be avoided by making use of vicious plastics that allow air to escape easily.

- Short shot: This term refers to a situation where the molten plastic does not make it to all parts of the mold cavity. This occurs when the plastic is too vicious, therefore solidifies before reaching the rear parts of the cavity.

- Jetting: This is a case where molten plastic refuses to stick to the mold surface as a result of fast injection speed. This situation occurs when the melting temperature is too low and the viscosity of the resin becomes too high, therefore causing the resin to cool down rapidly when it contacts the mold wall.

Insert Molding vs Over Molding: Which One Is Better

Insert molding and over molding are two different but similar molding processes.

Over Molding is a step-by-step injection molding process where two or more plastic components are molded on each other. This type of molding is very common for products that require handles. The body is molded first while the handle is molded over. Another example is a toothbrush where the plastic is molded, then the rubber is attached after.

Insert molding on the other hand is a molding process where the Insert is firmly encapsulated into the plastic with the use of mold cavity, plastic, and high pressure. This process helps manufacturers reduce production cost and also attain a customizable design to suit consumer needs/wants.

For some products, the iron (insert) part will always be the primary component while plastic quoting remains secondary. And there are also products that must be fully plastic quotes. So to decide which is better, your needs and wants must be considered.

Conclusion

The insert molding process has been able to help industries across all sectors tackle major product shortcomings over the years. And with the constant development of injection molding companies, upcoming products and services are bound to break more milestones in the coming years.

If you’re in need of insert molded products without having to worry about safety, contact Seaskymedical. We make use of the best injection molding in clean room technology and also apply automated equipment to reduce human contact on products.