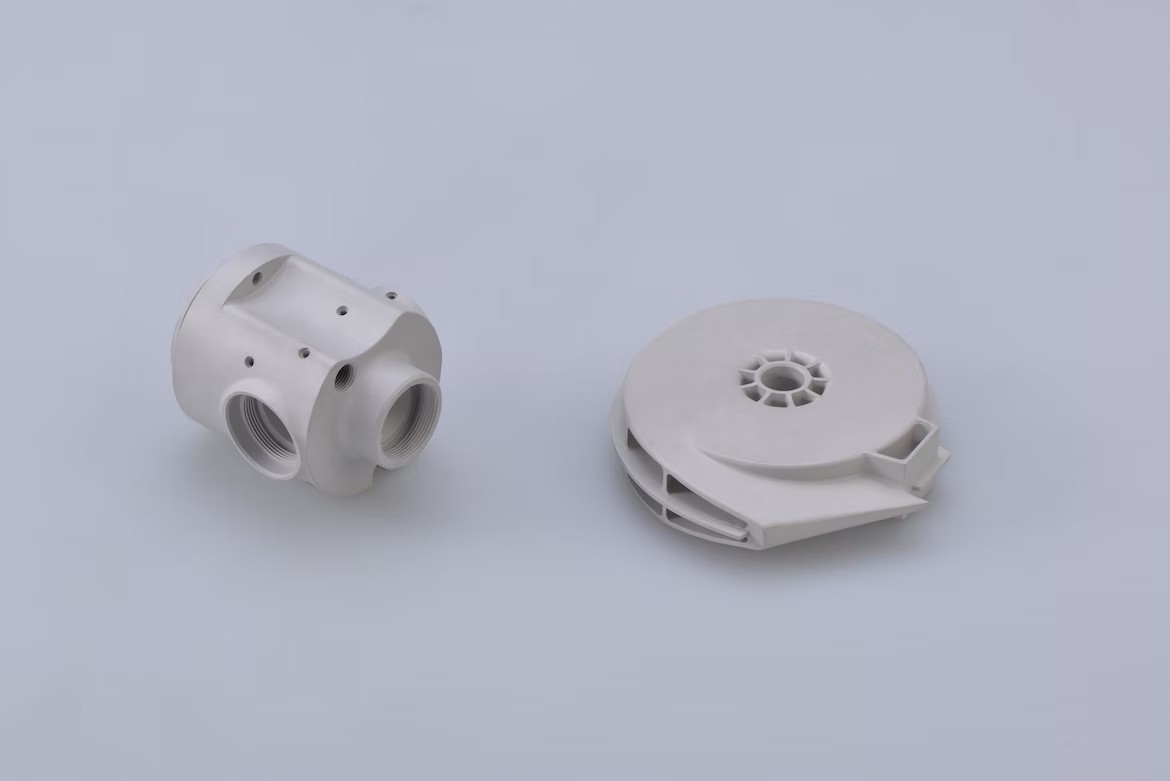

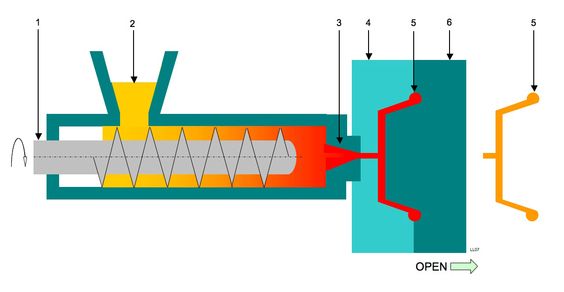

Injection molding is a popular manufacturing method used by injection molding companies to produce large quantities of plastic parts. The runner system is a crucial component of an injection mold that directs the molten plastic to the cavities. The injection molding runner design can significantly affect the quality of the final product, cycle time, and production cost.

In this article, it will discuss the injection molding runner design guidelines that can help businesses optimize the runner system for specific injection molding application.

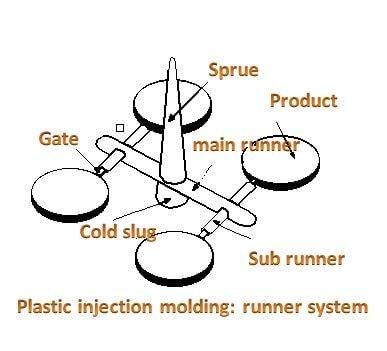

What is a Runner in Injection Molding?

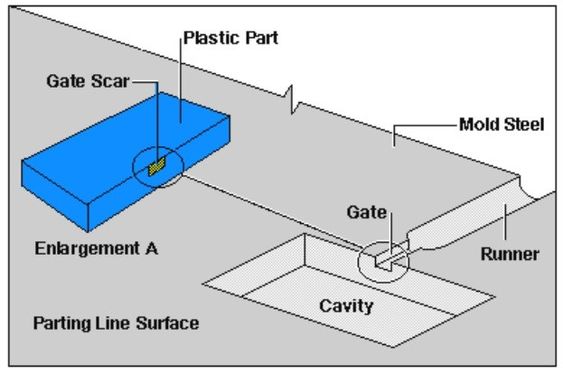

In injection molding, a runner is a channel that delivers molten plastic from the machine’s nozzle to the mold’s cavities. The runner system includes various components, such as sprue, runners, and gates, that work together to direct the plastic flow into the cavities. The size, shape, and location of the runner system can significantly impact the final product’s quality, cycle time, and production cost.

A well runner design injection molding ensures that the plastic is distributed evenly into the cavities, resulting in consistent part quality and reduced waste. The runner system is an essential part of the injection molding process and requires careful consideration and optimization to ensure a successful and efficient production run.

How Runner Design Affects Your Plastic Parts

The injection mold runner design can have a significant impact on the quality and consistency of the plastic parts produced. Here are some ways in which runner design affects plastic parts:

- Fill time: The size and shape of the runner system can affect how quickly the molten plastic fills the mold cavities. A poorly runner design system can lead to uneven filling, resulting in parts with incomplete or inconsistent features.

- Part quality: The runner system can also impact the quality of the final parts. An improperly designed runner system can cause cosmetic defects, such as warping, sink marks, or surface blemishes, that may render the parts unusable.

- Material usage: The runner design injection molding can impact how much plastic material is required to produce the parts. A poorly designed runner system can lead to excessive material waste, resulting in increased production costs.

- Cycle time: The runner system’s design can also affect the cycle time of the injection molding process. A well-designed runner system can help reduce cycle time, leading to increased production efficiency and decreased costs.

Runner Layout Design Guidelines

In injection molding runner design, there are several guidelines to consider to ensure an efficient and effective process. Here are some essential runner layout design guidelines:

- Keep the runner system as short and straight as possible to reduce the cycle time and minimize the pressure loss.

- Minimize the number of runners and gates, as this reduces the material waste and minimizes the potential for defects.

- Ensure the runner system’s diameter is consistent and appropriate for the part’s size and complexity, as this helps ensure a consistent flow of molten plastic.

- Position the gates at the thickest part of the part, as this helps ensure proper filling and reduces the potential for defects.

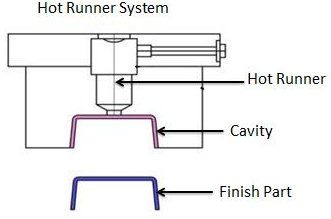

- Consider using a hot runner system in injection moulding to reduce the material waste and cycle time and increase production efficiency.

- Use a runner balance analysis to optimize the runner layout, ensuring an even distribution of plastic flow into the mold cavities.

- Use a design with a minimum number of sharp turns, as this reduces the potential for shearing and other defects.

- Use a design that is easy to clean and maintain, as this helps reduce the potential for contamination or blockages.

Design Guidelines for Runner System

In injection mold runner design there are guidelines to consider to ensure optimal performance and high-quality parts. The following are some essential design guidelines for the two types of runners in injection moulding.

Hot Runner Design

Hot runner design is an essential aspect in the pro injection molding as it affects the quality and efficiency of production. Here are some guidelines to consider:

- Choose a hot runner system with a modular design that allows for easy customization and maintenance. This ensures that any necessary adjustments can be made quickly and efficiently.

- Use a hot runner system with a consistent melt flow to ensure consistent part quality. This results in less material waste and increased production efficiency.

- The hot runner design should have an appropriate temperature control system to avoid overheating or underheating the plastic. This ensures that the plastic is maintained at the correct temperature for optimal flow and part quality.

- Use a hot runner system with a balanced flow to ensure an even distribution of plastic into the mold cavities. This reduces the risk of defects and inconsistencies in the finished product.

- Select a hot runner design with durable and reliable construction to reduce maintenance and repair costs. This ensures that the system lasts for as long as possible, reducing downtime and increasing productivity.

- Consider using a hot tip hot runner system that reduces material waste and cycle time by maintaining a constant temperature at the gate. This results in a more efficient production process with less waste material.

- The hot runner design must have safety features to prevent overheating and potential hazards. This ensures the safety of the workers and the production facility.

Cold Runner Design

Cold runner design is a critical aspect of injection molding as it impacts material waste, production costs, and part quality. Here are some guidelines to consider:

- Cold runner systems lower material waste and production costs. Optimizing runner layout and lowering gates and runners reduces those waste and costs.

- Design the cold runner system with a consistent diameter to ensure an even flow of plastic. This ensures that the plastic flows evenly through the system and into the mold cavities.

- Position the gates at the thickest part of the part to ensure proper filling and minimize the potential for defects. This ensures that the plastic fills the mold cavities properly.

- Use a runner balance analysis to optimize the runner layout and ensure an even distribution of plastic into the mold cavities. This analysis helps to identify any imbalances in the runner system and ensures an even flow of plastic.

- Minimize the number of runners and gates to reduce material waste and minimize the potential for defects. By reducing the number of runners and gates, you can minimize material waste and reduce the potential for defects in the finished parts. There are runner and gating design handbook that also might help in doing this.

- Design the cold runner system with a cooling system to avoid heat buildup and reduce the potential for warping or deformation of the parts.

- Choose a material that can withstand the temperature and pressure of the injection molding process and is resistant to wear and corrosion. This ensures the longevity and durability of the runner system.

Design Standards for Runner

When it comes to injection mold runner design, there are design standards to consider to ensure the best possible outcome for each part.

- Runner Diameter: The diameter of the runner should be consistent and appropriate for the size and complexity of the part in clean room injection moulding. Typically, the diameter should be between 4-8mm.

- Runner Length: The runner should be as short as possible to reduce cycle time and material waste.

- Runner Shape: The runner should have a smooth and streamlined shape to minimize pressure loss and optimize plastic flow.

- Runner Layout: The cold or hot runner design layout should be designed with a minimum number of sharp turns and angles to reduce the potential for shearing and other defects.

- Gate Location: The gate should be located at the thickest part of the part to ensure proper filling and minimize the potential for defects.

- Gate Size: The gate size should be appropriate for the part’s size and complexity to ensure a consistent flow of molten plastic.

- Material Selection: The material used for the runner should be able to withstand the temperature and pressure of the injection molding process and be resistant to wear and corrosion.

- Cooling System: The injection mold runner design should have a cooling system in place to avoid heat buildup and reduce the potential for warping or deformation of the parts.

- Runner Balance Analysis: Use a runner balance analysis to optimize the runner layout, ensuring an even distribution of plastic flow into the mold cavities.

Considerations When Carrying Out Runner Design Injection Molding

When carrying out runner design injection molding, there are few considerations that should be taken into account to ensure that the molding process is efficient and produces high-quality parts.

- Material properties: The material factors such as melt temperature, viscosity, and flow rate should be taken into account to ensure that the runner system can deliver the material to the mold cavity at the right temperature and with the right flow rate.

- Part design: To achieve uniform material flow and prevent the formation of air pockets or other imperfections, it is essential to optimize the size and configuration of the runner system. The choice between a cold or hot runner injection molding process may also impact this optimization.

- Mold design: The runner system should be designed to minimize pressure drop and ensure that the material flows evenly throughout the mold cavity. There are some manufacturers who offer custom plastic injection molding as well.

- Injection molding machine: To ensure a smooth and uninterrupted flow of material through the runner system and into the mold cavity, it is important to carefully adjust injection pressure, velocity, and other relevant parameters.

- Cost considerations: The cost of producing the runner system should also be taken into account. The injection molding runner design should be fine-tuned to minimize material waste and reduce the time and cost required to manufacture the runner system.

Get Free Mold Design Service From Seaskymedical

Seaskymedical is one of the trusted medical plastic manufacturers across the globe, providing high-quality injection molding services to clients worldwide. As a part of our commitment to providing the best possible service to our clients, Seaskymedical is now offering free mold design services for all of its clients.

Seaskymedical’s team of experts can help every business create the perfect runner design injection molding for our medical device or other plastic product. Our experienced designers use the latest design software and technologies to create detailed 3D models and simulations, ensuring that every medical device injection molding is optimized for quality and efficiency.

By taking advantage of this free mold design service from Seaskymedical, businesses can save time and money while getting the highest quality mold design possible. We will work closely with our team of experts to ensure that every business mold design meets our exact specifications and is tailored to its specific application.

Whether a business working on a complex medical device or a simple plastic product, Seaskymedical can help you create the perfect mold design for your needs. With the company’s years of experience and commitment to quality, anyone can trust Seaskymedical to deliver the best possible service and results.

Final Thoughts on Injection Molding Runner Design

Injection molding runner design plays a crucial role in the quality and efficiency of the injection molding process. There are different types of hot runner mould and cold runner mould, and by considering a series of factors, you can optimize your runner system for high-quality, efficient production.

At Seaskymedical, we understand the importance of runner design in injection molding and are committed to offering the best possible service to our clients. To take advantage of this free mold design service, simply contact Seaskymedical today and speak with one of our representatives or visit our website. We will be happy to answer any questions and get started on the mold design right away!

Frequently Asked Questions

Here are some frequently asked questions to help you better understand injection mold runner design.

What are the Different Types of Runners in Injection Molding?

There are two main types of runners. Hot runners, including insulated runner molds, are heated manifold systems that keep the plastic in a molten state as it flows through the runner system. Insulated runner mould is a type of hot runner system that uses a runner system that is insulated from the mold plates, which allows the plastic to stay at a consistent temperature and flow more evenly into the mold cavities.

On the other hand, cold runners are unheated channels that allow the plastic to solidify before being ejected from the mold. While cold runners can result in longer cycle times and waste more material than hot runners, they are often less expensive and easier to maintain.

How Do You Calculate Runner Length for Injection Molding?

When it comes to injection molding, one of the most important steps in the process of designing runners is calculating the length of the runner. The length of the runner will have an effect on the pressure and flow rate of the plastic as it moves through the runner system.

Calculating the length of the runner is a complicated process that needs to take into account a variety of variables, including the part design, the material is chosen, and the runner layout. In most cases, the length of the hot runner system injection molding is calculated by applying a formula that takes into account both the pressure drop and the pace at which the plastic is flowing.

However, there are a lot of other variables that need to be considered in order to ensure that the runner length is optimal, and this calculation is something that should only be done by a knowledgeable injection molding engineer or designer.