Mold maintenance refers to cleaning the tools so as to keep them working in order. Similarly, repairing is also done to prevent wear and tear for the best functioning of the plastic injection mold.

For a successful long-run molding program, mold maintenance holds a lot of importance. Sadly, many buyers tend to ignore it. This will also help in smooth functioning and will also prevent loss.

Small defects that can transform into a bigger issue can be prevented in a go. Also, the loss you face and the unnecessary expenditure for the entire repairing process can be resisted.

Methods to Maintain

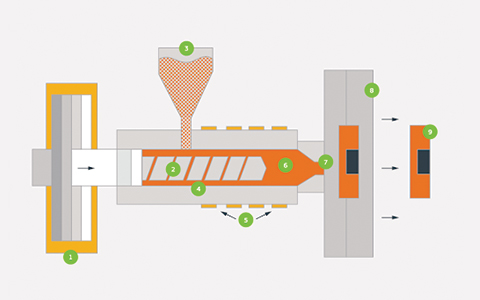

Here, we will be an idea of the basic routine for mold maintenance and then followed by a more advanced one.

Basic routine for maintenance

The basic routine for maintenance are :

- Basic maintenance before and after every cycle.

- Clean mold cavities with a gentle solvent.

- Use compressed air to blow out the dust, debris, and water.

- Ensure the dryness of the mold.

- Check runners and all other parts of the mold.

- Check mold hardware and connectors.

- Note the dates of your mold maintenance steps.

Basic maintenance before and after every cycle – Attentively looking for any dust, and debris before the cycle and especially after the cycle will prevent a lot. This will detect the issue in no time and not compromise with the standard of the cycle.

Clean mold cavities with a gentle solvent- Residue within the cavity can hamper the shape and size of the integral process. So, simple cleaning works a long way. With the gentle solvent, they will not affect the mechanism of the system.

Use compressed air to blow out the dust, debris, and water- For simpler molds cleaning can be easy. But, for complex molds reaching out to the extreme interior can be a tough job. Moreover, this residue in the interior can lead to a severe issue in the system.

So, using compressed air can blow out the dust, debris, and water.

Ensure the dryness of the mold- Keeping the molds dry before storage is a very crucial need. As the water in the mold can lead to rust which can damage the entire mold. This can result in the production of destroyed products.

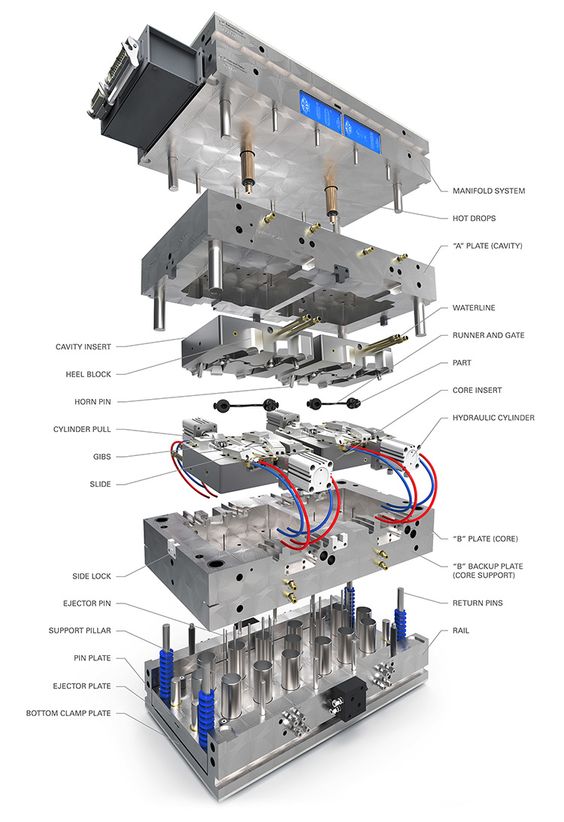

Check runners and all other parts of the mold- The mold cavity is not the only area that needs to be checked. The other parts of the mold such as runners or sprues also need inspection as dust and debris can affect these too.

Check mold hardware and connectors- The inspection of the external parts such as bolts, plates, etc also needs to be carried out. This will look for wear, tightness, or other standard maintenance issues.

Note the dates of your mold maintenance steps- Keeping a note of when the inspection was conducted is the best way to not miss out, The tracking system will help the work at this end be completed very smoothly.

General routine for maintenance

This routine has to be performed by trained professionals only. The first and foremost step is to separate all the plates.

To clean the polish surface, extra precautions need to be taken. Facial tissue or cotton balls should be used and some liquid solvent must be spread. Avoid touching with bare hands.

As mentioned above, checking the cavity before blowing for dust is vital. There has to be no negligence in this regard.

Secondly, lubricating every part is another crucial demand. Vents should be checked for dimensions and if that is creating an issue in the cycle or not. Corrosion and vent burns are other common havoc that runs around vents.

Integrity check of “O” rings, seals and gasket is the next step. Pressure tests and rectification of flow capacity should also be checked.

Alignment of the ejector system, springs, etc must be analyzed and determined.

Advanced Routine For Maintenance

This injection molding maintenance process can be carried out only with proper tools and skilled personnel.

The maintenance procedure in this regard is quite complex. But, it can detect minute issues that can transform into a bigger headache in the long run.

There are steps in this routine, that can stand no negligence. That is why professionals with knowledge in the subject are always favored for the job.

Before the process initiates, there have to be four complete shots delivered with the tooling for study.

The first shot will give a visual depiction of what the mold was like when it was new and without any wear and tear.

The second two shots are the most recent parts produced just before the tool was pulled for maintenance. The difference in the two scenarios can give an exact idea of what has changed over time.

The wear and tear will be crystal clear and that will help them in ruling them out completely. After that, all the components that have problems should be removed, and new components are installed in accordance with the initial authorization of the mold.

Worn leader pins, bushings, and ball-bearing moving surfaces are the next things that need attention. This is followed by plates and mold cavities.

Mold cavities should also be polished as per the original requirement. Not just this, in fact, any component that is not in accordance with the original requirement of the mold must be replaced.

Components that are prone to corrosion should also be shielded from the same lubricants. Hardness and other relevant requirements of every concerning component should be checked thoroughly.

Water lines, “O” rings, gaskets, and all other components should undergo inspection. Every external section of the mold including the base needs inspection for cracks if any.

The cavity surface needs to be cleaned. Moreover, if the proper way of polishing the same is followed, the surface will look good as new for a really long time.

Texture changes, however, are not restricted.

Plastic overmolding will also have to undergo these steps for maintenance. Manufacturers that deal with CNC mold making and injection molding tool can be a great help for this.

Ways to repair

As of now, we have a detailed idea on maintenance and some glimpse of injection mold repair as well, let us look forward to more of the same.

Medical plastic injection molding has a vital role in medical device industries as well. So, there are various medical injection molding company on service. Hence, the mold repairment should have no negligence whatsoever.

For repairing, one thing that needs undivided attention is that it has to be in a structured sequence.

The benefit of working in an assigned sequence is that it reduces mental blunders, enhances troubleshooting skills and accuracy, and reduces repair time.

Now, coming to the main discussion that is repairing. There are eight stages for that and it goes like this:

- Preparation

- Dissembling

- Troubleshooting

- Corrective action

- Cleaning

- Assembling

- Final Check

- Staging

Preparation

The technician should know what he is dealing with. Giving him the record of all the past issues, followed by what corrective measures have been adapted is the gateway to the entire process.

This will help them customize their way for further activity so that they do not end up hampering something. The process can get elongated this way, but not going through this can lead to severe loss.

Dissembling

Dissembling all the parts is the next step. Mold dissembling should not be done haphazardly. The cycle needs to be taken care of. Arbitrarily doing so, can lead to some severe damage, waste manpower and time.

In industry, three levels of disassembly are very common those are Wipe-down, General, and Major Disassembly. There is also a fourth step, which is carried out time-to-time by certain industries only.

Troubleshooting

This step is dependent on the technician’s ability. Accurate detection of the past and present issues are made out with proper inspection and historical records. The entire troubleshooting procedure of plastic injection mold repair needs to be planned post that. Followed by that, everything needs to be noted on how things will continue to work.

All the issues should be segregated and corrections must be made one at a time.

Corrective action

Now comes the main step of the entire process. After the detection of the whereabouts, this is what needs to be done.

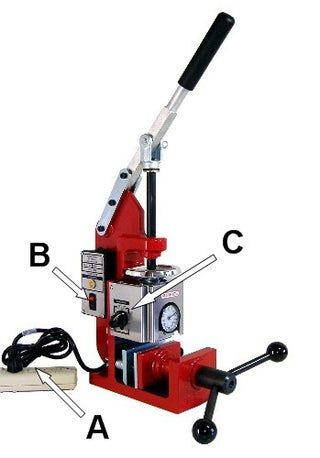

The sheer inspection will mean nothing if this step sees failure. The repair technician’s ability along with skilled tools comes under service at this point.

Everything shares equal importance at this point. If there is leniency in one sector, it will bore a bad result for the entire system.

Cleaning

After the solving process is carried out, this is where it goes. Cleaning should not be underestimated as it is can lead to further damage. Keep all the instruments that were in use away and concentrate on this.

Cleaning, again, should not be done abruptly. The cycle, here, is the main point of concern. The method, type, and frequency of cleaning are based on cycles, hours, and the materials that were in use as well.

Assembling

As the cleaning is done and dusted, now comes the time to assemble the mess and put together everything. Accurate and skilled tools should be used in the process so that the fixation is done appropriately.

The personnel is supposed to be skilled and there has to be no rush in this step. If there is a time constraint, the proper time duration for this step needs to be fixed.

If there comes any issue after this step it is mainly due to lack of focus, physical skill, and disorganized work habits. Also, if several repairs techs are involved in assembling, this can lead to a breakdown of the entire system resulting in dissembling.

Final Check

Many plastic mold manufacturing companies tend to ignore this step, but we suggest not to. To err is to be human. The technician may leave some tits and bits of error here and there which can destroy the entire setup.

So, a final check of the internal and external alignment is a must need. There is a lot of time when some minute issues get detected at this step which could bring the mold back to the shop for repairment.

Another very important reason for this is that it will help any bigger issue get detected while it is easily solvable.

Staging

After all the steps of dissembling, troubleshooting, corrective actions, cleaning, assembling, and final check are carried out, it needs to get stored. Now, that is also a very crucial step.

There has to be no rearrangement or mismatch with the sequence.

If the storing space has some issues this can straight up affect the mold and that will put all the steps into vain. So, the storage area needs to be preplanned beforehand.

If all these steps of repairs are carried out with utmost sincerity, there is a surety of witnessing no failure in the future as well.

Conclusion

In this blog, we have given a detailed idea of how the maintenance and repairing process is carried out in molding. From that, it can easily be inferred that effective tooling and workmanship is the key and not a single step can work out without these.

Also, as mentioned above, the sequence holds great importance as well. Few of the steps may sound really irrelevant as they may not bring any result at the moment. But, that is not how it works.

When businesses look forward to mold maintenance and repairing, they want it to be effective for a long time. Now, to make that happen, having every detail inspected and corrected is the only way through. You can also hire professional custom mold manufacturers to assist you with the process.