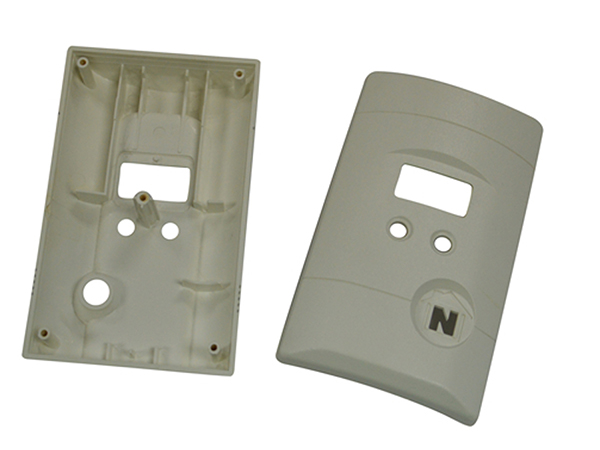

When it comes to rapid prototyping and plastic production parts, any medical molding company will agree that injection molding is an excellent manufacturing procedure. Defects in the plastic molded parts, such as sink marks and flow marks, might occur if the manufacturing process is not strictly regulated. Injection molding frequently has multiple flaws. If a medical plastic injection molding companywant to get the most out of its equipment, it should do everything it can to reduce the frequency with which these problems arise. Growing levels of competition can be seen in the plastics industry.

Modern buyers have more knowledge and alternatives than ever before. They desire spotless products which are no short of visual perfection. Imperfections in manufactured plastic goods, such as a flow line defect in injection molding, are unacceptable. These flaws might have an impact on the product’s functionality as well as its appearance. For instance, the plastic used for gears must be completely smooth. Errors like these manifest when processing is done incorrectly. In injection molding, flaws like flow markings have to be avoided at all costs. This article sheds light on the measures made to avert such an occurrence.

What Is a Flow Mark in Injection molding?

Flow marks, also known as gate marks, can take the form of either a circle or a set of parallel lines. Even after the product has cooled, the marks are still discernible. They show that the flow of material into the mold was not uniform. The temperature gradient within the melt is to blame for the resulting nonuniform flow. Light refraction contributes to the subtle variation in hue between these flow marks. It also arises from a reorganisation of pigments in the body.

In a perfect world, these problems would surface during the practice runs. As soon as an engineer discovers such a flaw, corrective action is taken. In the first place, this is avoided thanks to the process and the mold’s superior design. Early detection of the flow mark can prevent a lot of problems and costs.

How to Fix Flow Mark on Plastic Parts?

After the fact, there is nothing one can do to fix the issue. The component is unacceptable and must be sent for recycling. It’s crucial to put in place checks that can identify issues like these. It is ideal for spotting the flow mark as soon as possible. This is probably not a one-off occurrence, but rather something that will occur again in the subsequent cycle. The sooner it is found, the less damage there will be. Therefore, it is the responsibility of process engineers to implement checks for finding flaws.

In an ideal situation, the problem would be spotted before it even happened. To do this, it is necessary to understand the contributing factors that cause this flaw. Finding the problem before it happens saves effort and time. Temperature and melt flow rate are two parameters that can be used as early warning systems for flaws.

What Are the Reasons for Flow Mark in Injection molding?

A Flow mark in injection moldingcan appear for a variety of reasons, although in most cases they are the consequence of the plastic cooling at different rates. This uneven cooling can be attributed to a number of factors, some of which will be discussed below, including the type of material used, the type of machinery used, and the design of the mold or molds in question.

Material Causes

In order to minimise the flow line defect in injection molding during the injection molding process, it is crucial to monitor the material temperature as it is being injected. Melt Flow Index (MFI) is an indicator of the flow characteristics of a melted thermoplastic; lower MFIs are more susceptible to flow markings. The temperature has a major role in meeting this criterion because plastics are known to be temperamental around hot or cold. When the temperature is too high, the plastic degrades, but when it is too low, flow markings become more noticeable.

The appearance of flow marks can also be the result of an insufficient injection speed or an incorrect flow rate. If the injection rate drops off as the plastic nears the mold’s interior, the material will cool too quickly and leave flow markings. If the material’s temperature drops too much before it enters the mold, flow markings will form in the plastic.

Machine Causes

Flow defects are often caused by adjusting one of the machine’s settings. The material will not melt consistently through the mold if the machine injection pressure is too low, leading to uneven cooling. The same holds true for the nozzle and barrel: not heating the plastic enough will cause it not to flow properly. Lack of sufficient residency and cycling durations might lead to uneven cooling and flow markings.

Toxic Mold/Mold Construction

The reason for flow mark in injection molding can also be the molds that were poorly developed. Bad outcomes can be expected from molds with insufficient ventilation, uneven wall thicknesses, and inadequate lubrication. The frequency of flow marks is additionally determined by the design of the sprue, gate, and runner. If the gates or runners are too narrow or too thin, the material flow, temperature, and pressure will be reduced, leading to a host of problems, most notably flow markings.

After knowing the causes, it is significant to know how to control flow mark in injection molding in detail.

How to Control Flow Marks in Injection molding?

Flow mark troubleshooting in injection moldingwill requirefine-tuning, experimentation, and clever planning. The best strategies to reduce the appearance of flow markings in an injection mold are detailed below, but before making any adjustments, it is essential to determine the root cause of the problem. So, how to avoid flow mark in injection molding? The steps mentioned below will answer this question.

Deviations in Pressure Measurements

Increasing the injection molding machine’s back and holding pressure is a simple solution. Increasing the back pressure will force more fluid through the mold’s runners and improve compaction. By forcing the plastic to better conform to the mold cavity’s finish, increasing the holding pressure (or the static pressure once the plastic is injected) improves surface quality. Keep in mind that too much injection pressure might cause jetting, another flaw that strikes a happy medium by adjusting other factors.

Variations in Temperature Standards

Because both the machine and the mold contribute heat to the process, making drastic adjustments to either can have unintended consequences. Because of the close relationship between pressure and temperature, low melt temperatures may initially appear to be a pressure issue. It is important to check that the temperature in the barrel is within the range specified by the manufacturer. The suggested barrel temperatures for most thermoplastics designed for injection molding are included in the packaging, however, manufacturers typically allow for some leeway.

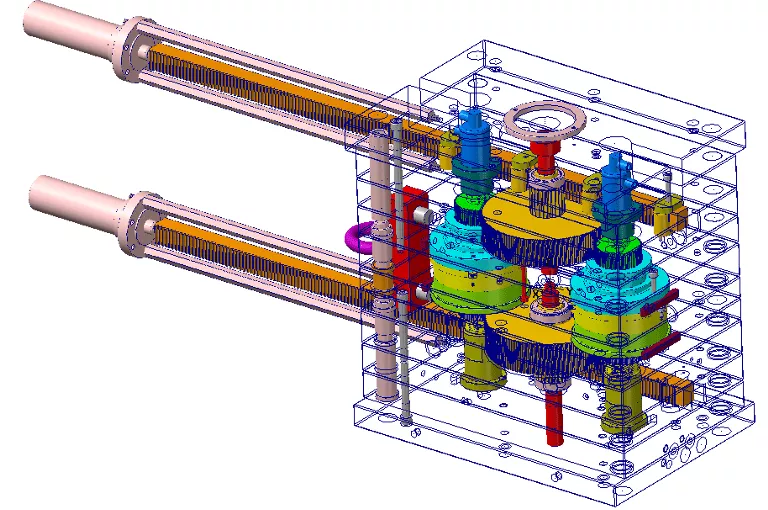

Keep in mind that the nozzle, the centre, the back, and the front are each their own heating band (shown in the above diagram as the three heaters around the barrel and the nozzle itself). The temperature should be increased by +6°C per zone as the plastic is pushed through the barrel. Always begin with the suggested temperature for the barrel, nozzle, and mold, then test ten or so mold samples, analyse the data, and make any necessary adjustments.

Lightning-Fast Injections

When the injection pressure is increased, the injection rate is correspondingly increased. Injection molding requires high speeds because at low rates the molten material has more time to cool, resulting in fewer flow lines. To improve flow and delay cooling, a larger nozzle diameter can be used if necessary.

A too-stiff molten polymer will slow down injection regardless of pressure or speed, therefore material also plays a role. Filling speed is slowed, leading to uneven cooling, if the molten plastic is thick and the gate is narrow. Use the recommended flow rate of a material with a stiff flow to prevent non-fill and speed up the flow process.

Making a Gate, Sprue, and Runner

The design of the gate, sprue, and runner is crucial, as thin or narrow gates and runners will limit the flow of the material, lowering the pressure, the injection speed, and ultimately the temperature. Fortunately, simulation software (like C-MOLD) can determine the optimal gate, sprue, and runner diameters for the mold. Having gates closer to thinner or colder sections of the mold will reduce cooling time and enhance the frequency of flow lines. When changing entry points, keep in mind that certain components have fixed gate locations to optimise filling.

Venting

Once the molten plastic has been poured into the mold, the venting system allows the air that has been trapped in the mold cavity to escape. Install openings at the conclusion of each runner segment and possibly those on either side of the gate as well. The vent depth depends on the plastic’s viscosity; in general, though, stiffer materials require deeper vents. As an added bonus, computer simulations can reveal where the melt will fill last, giving a better idea of where to position the ventilation systems for maximum efficiency.

Design of the Mold

Uneven flow and cooling are the results of sharp corners and edges in the cavity. Fillet edges and rounded corners can be used for injection molding tool design for better material flow and less noticeable flow marks. Consider the impact that wall thickness has on cooling as well. This effect is not a concern for molds with consistent wall thickness, but it can worsen the cooling process for those with more variation. Wall thickness should vary continuously across the section, with more fillets and rounded corners in the thicker regions as a general rule. If one wants to avoid clogs and cooling concerns, install a cold slug well at the primary runner’s outlet.

The Expertise of the Operator

Last but not least, a plastic material selection guide or educating operators on proper practices and the injection molding process can help minimize flow marks in manufactured parts. In the event that the injection molding machine is not automatically cycled, it is crucial that operators have a firm grasp of the proper cycling time in order to ensure consistent molding cycles. More emphasis should be placed on lubricating parts of the mold with a high flow length-to-wall thickness ratio (in accordance with material specifications). Work shifting also helps cut down on mistakes brought on by complacency or weariness, although many of the aforementioned issues can be resolved by switching to robotics/control systems.

Get Closer to the mold From the Hot Nozzle

The greater the distance the melt has to travel, the faster it will cool. The melt must be hot enough when it enters the mold but not hot enough to solidify. A hot runner can be used when the distance cannot be decreased further. That way, the melt won’t cool off before it’s poured into the mold.

Gate Location

To what extent the gate’s location matters is a question of some significance. Although there may be guidelines for where the gate must be placed on certain products. Injection molding is commonly used to create gears. In this case, the gate is placed smack in the middle of the gear for maximum loading efficiency. In cases where rules are not specified, the gate should be placed on the side of the mold where the wall is the thinnest. Due to the reduced temperature transfer caused by the thinner walls. For that reason, the mold’s flow patterns won’t be disturbed. There is an initial temperature differential between the thinnest and thickest walls, but this is quickly balanced as the melt moves upwards.

Seaskymedical – Your Best Plastic Injection Molding Partner

As its name suggests, Seaskymedical specializes in medical injection molding, but it also performs standard custom plastic injection molding. It further offers safe alternatives in the field of medical injection molding. From conceptualization to manufacturing, the company does it all, from product design to mold-making to raw material selection and injection molding.

It has been developing molds and producing plastic parts using an injection molding process that is both precise and reliable for over a decade.

Moreover, they benefit from their parent company’s more than 11 years of experience in project management and supply chain management. Their ISO 8 cleanroom and 10 state-of-the-art injection molding machines allow them to address the varied demands and exacting requirements of the medical industry.

When it comes to the production difficulties of medical items, SeaskyMedical employs cutting-edge injection molding technology. By synthesizing knowledge from production procedures, data analysis, and personalised risk mitigation, they are able to serve each client with the utmost professionalism and integrity. As a global provider of medical plastics modification services, they’ve been in business for 12 years. Because of their extensive background in the selection of plastics for use in the medical industry, they can help clients significantly lower their risk during product development.

There are some new manufacturing facilities in this sector as a direct result of the pandemic. Extremely high rates of product return, and the inability of some scrapped molds to enhance the product’s purity, especially with regard to oil pollution. The development of medical molds and medical injection molding is an area in which they can offer extensive, complimentary technical support and services to our clients.

Conclusion

There are ways to avoid the unsightly flow mark that often appears on injection-molded products. However, once it has occurred on a product, it is usually unacceptable. It may not change the product’s performance, but it can drastically alter its marketability. Keeping the environment stable and using a mold, gate, and runner system that works well for the task at hand. This aids in the avoidance of flow markings. Contact Seasky Medical for plastic injection molding.