Molding is the process of shaping or forming raw plastic into the form or shape that will be used for the finished product. Each product calls for a unique molding method. The overmolding process and insert molding design types are generally acknowledged as the most successful molding techniques now available on the market.

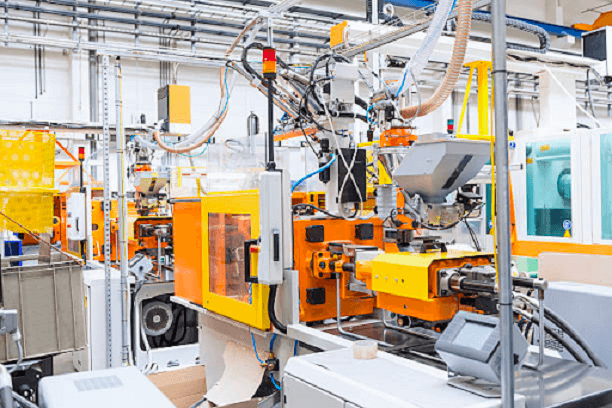

Molding is the process of shaping or forming raw plastic into the form or shape that will be used for the finished product. It is extensively employed in manufacturing various products, including bottles, automobile components, and medical apparatus.

There are many different kinds of molding, such as injection molding, blow molding, and compression molding. Molding techniques are specific to each product; nevertheless, the over-molding process and insert molding design types are generally acknowledged as the most successful molding procedures available on the market.

The first stage in a typical plastic manufacturing process is to heat a resin to the required temperature. The resin is then mixed with the necessary additives and placed in molds. Extra material is removed after the plastic has cooled, and the finished product is ready for sale.

This article will explain insert molding design works and the advantages and best practices of insert molding solutions.

Why Choose Design Insert Molding

Design Insert Molding is gaining in popularity due to its advantages. Which include high precision, the ability to be manufactured, and the simplicity of its application.

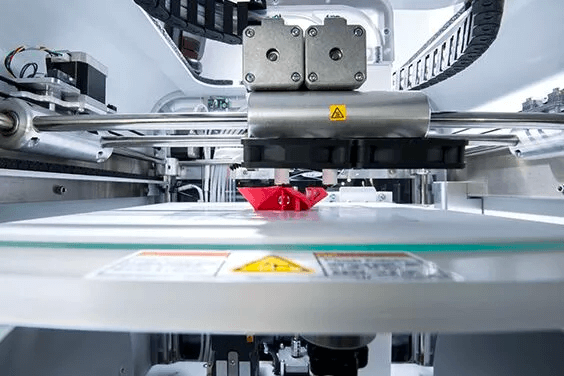

Molding can take many forms, one of them is called “Design Insert Molding.” This form of molding dispenses with the need for standard production processes and makes it possible for designers to produce intricate designs rapidly.

There are many different advantages of selecting design insert molding; some of these advantages include the following:

Increased Design

Insert molding allows for incorporating characteristics that would otherwise be impossible or difficult to achieve while developing a product. For instance, it can add a textured grip to a handle or raised lettering to a consumer electronics device.

Faster Production Time

Insert molding can be faster than traditional methods like machining or assembly. The entire cycle time is shortened since the inserts are inserted in the mold before the molding begins.

Less Expensive

Insert molding is typically less expensive than other manufacturing techniques. This is because secondary procedures such as machining and assembly have been eliminated.

Increased Durability

Insert-molded goods are often more durable than those produced using conventional methods. Because the inserts are molded into the product, a stronger bond between the two sections is formed.

Greater Accuracy

Insert molding can produce things with more dimensional precision than other technologies. Before the molding process begins, the inserts are precisely inserted into the mold to verify that they are in the correct location.

Few Parts

Insert molding is fewer components involved. Insert molding typically results in the production of goods that have fewer flaws. Insert molding can reduce the number of individual features required to produce a single component. The end product will be of higher quality if it contains fewer components.

Flexibility

When necessary, insert molding is capable of handling both polymers and metals. As a result, it is a cost-effective option for those who want to create a wide range of products made from various raw materials.

How Does Insert Molding Work?

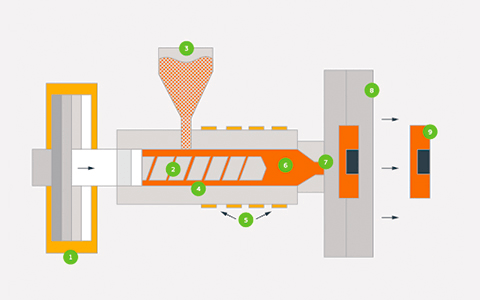

Insert molding is a procedure in which an already manufactured component is put into a mold before the molding process. Metals, polymers, and composites could all be used in their construction.

After the component has been installed, the necessary material is poured into the mold and left to cool. The finished product is a single piece that includes the insert.

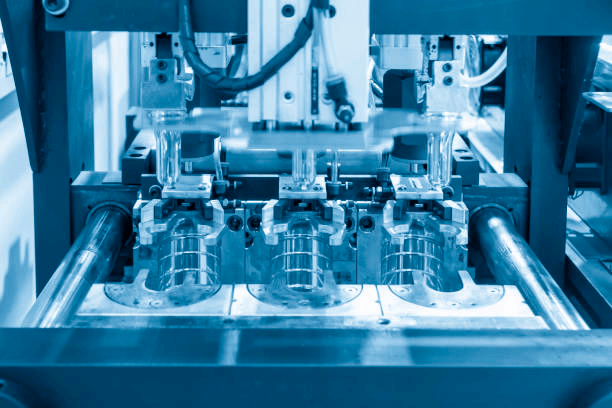

Moreover, insert molding follows the same fundamental principles as plastic injection molding. Molten resins are injected into a plastic mold fitted to the item’s geometric parameters. Plastic resins are injected into the mold and allowed to harden. After that, the inserts are extracted/ejected from the mold.

The only difference is that the metal is injected into the molten resin before the mold is closed. The plastic completely envelops the items in this manner, leaving no fractures and preserving uniform wall thickness.

The inserted product can be as simple as a blade or tube or as complex as a metal insert for a complex machine. Insert molding was chosen because it avoids using screws to attach multiple plastic components to a product’s cover.

The product is completely contained within the covering, and the covering is mechanically and naturally bonded to the product. Insert molding has various advantages. It is possible to save time and money by minimizing secondary assembly activities.

It boosts the longevity and stability of the final outcome by creating a stronger bond between the insert and the surrounding material. Furthermore, concealing the insert might improve the finished product’s overall appearance.

Insert molding is a versatile manufacturing technique that may be used to create various products. It is used in multiple automotive, aerospace, and medicine industries.

The Advantages of Insert Molding Design

Insert molding is the technique of molding two or more materials together to form a single product. Insert molding can be used to create a variety of products. Molding techniques such as compression, injection molding, and transfer molding are all viable options for achieving this result.

Insert molding is a common manufacturing technique utilized for making components with several functionalities or when attempting to increase the robustness of a component. When it comes to the design of a product, insert molding offers several benefits that should not be overlooked.

Here are the following insert mold advantages:

- Insert molding is a technique that can increase the component’s strength by fusing two or more materials together into a single part. This technique is frequently utilized in the automobile and aircraft industries, requiring components to endure intense stresses.

- Insert molding can produce highly adaptable components since it combines many materials. One example of something that can be manufactured in a single stage is a housing made of plastic with a metal inlay. During the production process, this might result in cost and time savings.

- Designers can produce components with a more finished appearance by using insert molding. A wood grain impression, for example, can be generated by inserting a wood veneer into the mold.

- Insert molding can cut production costs by reducing the number of operations required to create a component.

Things to Consider When Designing Insert Molding

When it comes to insert molding, a few crucial considerations must be considered to guarantee that the end result fulfills one’s expectations. Here are some of the things that should take into consideration:

Size

It is critical to consider both the mold size and the pieces that will be produced when planning to insert molding. The size of the mold will influence the size of the finished parts. The size of the components determines the amount of material used to make the mould.

Insert Molding Materials

The material of the insert must be compatible with the material of the mold. One must also consider the qualities of the insert material, as this can affect the final output.

Insert molding materials of various types can be used when developing insert molding. Common materials include:

Thermoplastic resin

This substance is commonly used for heat-resistant goods, such as polymers found in electronics. Furthermore, it is used in goods such as spectacles that are difficult or impossible to create using other molding materials.

Polypropylene

Polypropylene is a thermoplastic resin commonly used in water- and liquid-resistant products. This material is also widely utilized to make strong and long-lasting items.

Polystyrene

These are light, transparent polymers having a low melting point. They are acid and basic-resistant and are widely utilized in everyday mainstream products such as consumer goods and medical molding companies.

Polyethylene

This thermoplastic polymer is chemically resistant and has good toughness, dielectric properties, and impermeability. HDPE, MDPE, and LDPE are the most prevalent thermoplastic polyethylenes on the market. They are considered lightweight thermoplastic materials.

Nylon

Nylon is a chemically and abrasion-resistant material that is very strong. Because of its high melting point, it can be used in place of metal in some applications. For heavy-duty applications such as production and extraction, nylon injection molding is the material of choice.

Phenolic

The material is typically certified to IL 94V 0 and has good halogenated solvent chemical resistance. Highly specialized procedures are subject to certain constraints where they exist.

Epoxy

They become permanently hardened and have no melting point after processing. As a result, they are well-suited for high-performance applications. They have exceptional heat and chemical resistance, as well as exceptional adhesion.

Draft

When developing insert molding with draft, several factors must be considered. The location, size, and shape of the object to be molded must all be considered. Incorporating draft angles into a design makes a part easier to expel from a mold and improves its overall moldability.

The draft angle determines the space between the part’s mold and the casting surface. The draft angle is commonly measured in degrees from the vertical plane at the part’s ear point. If the ear point is below the surface of the casting, the draft angle is negative and refers to the side of the object that will be in contact with the mold.

The draft angle is positive if the ear point is placed above the surface of the casting. Additionally, it indicates the side of the part that will be facing away from the mold. The final dimension of the component will be determined by the drafting precision and tolerances.

Undercuts

Undercuts, common in molding, present regular design issues for inserts. Undercuts are defined as any recess in part. That prevents it from being pulled from the mold in a straight line.

On the other hand, more intricate undercuts are conceivable but can be costly to create. Undercuts are frequently eliminated by simply redesigning the component.

If this is not practicable, there are several techniques for producing inserts for undercut-molded parts. A mechanical locking device can secure inserts, such as a snap-fit or interference fit.

A second alternative is to use adhesive to attach the insert to the component. Combining this method with a mechanical mechanism is customary to prevent the implant from slipping free.

More detailed designs are required if the insert is to be detachable. One solution is to use a two-part mold with a core that can be pulled out of the cavity with the insert. This type of mold is more expensive and complicated to design and build.

Wall Thickness

When designing an insert molding, wall thickness is critical. The insert’s wall thickness determines the product’s strength and durability. The insert may fracture or crack if the wall thickness is insufficient. Extracting the insert from the mold may be difficult if the wall thickness is too thick.

Step by Step Insert Molding Design Guidelines

Insert molding is molding a plastic component around a metal insert. The insert is placed in the mold before adding the remaining plastic material. Threaded fasteners, such as screws, are routinely incorporated into plastic components in this manner.

Insert mold flow design is a routine technique that must be followed precisely to increase the likelihood of success. Below is the insert moulding design guide.

Preparing the Tools

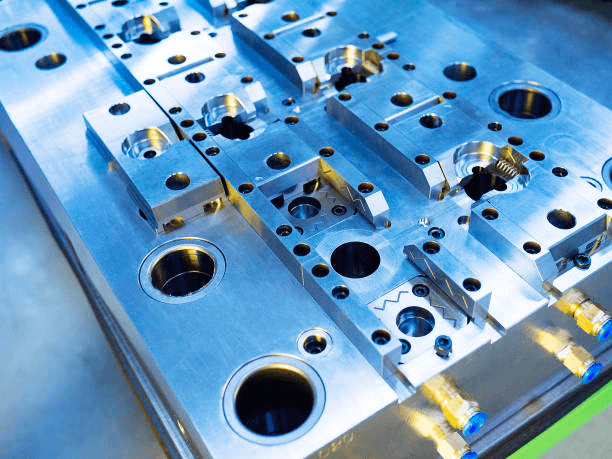

The first stage in planning insert molding is to prepare the machinery used in the technique. To ensure that the finished product is faultless, each component’s machine tolerances and alignment must be checked.

Inserts

The next step is to choose the inserts that will be used. Metal or plastic can be used in most situations. The two most common metals are brass and stainless steel. Almost anything will do for plastic. The molds are then put vertically into the machine to guarantee they stay in position once it starts up.

Threading

There are numerous thread possibilities for insert molding. The process of placing materials into a mold is referred to as threading. The goal is to ensure that the mold does not generate the product insert but rather stays functional and useable throughout downtimes.

Molding

When everything is in place, and the design is finished. It is time to put the machine to work and create the desired end product. The length of time it takes to complete a product is dictated by its size. Also, the nature of its components.

Conclusion

Material selection, tool design, and process control are variables in optimizing the insert molding design process. Manufacturers may avoid potential problems and boost their chances of success by ensuring that these critical variables are considered and by following the insert molding guidelines. The molding process might take many forms, but it always adheres to the same principles.

Seaskymedical applies innovative injection molding technology to all of its manufacturing difficulties to provide the medical business with the safest and most reliable equipment. The company, for more than a decade, has given low-risk, cost-effective solutions to the healthcare industry. Furthermore, it offers clients comprehensive and qualified assistance throughout all project phases.

If you are looking for a medical plastic manufacturer and supply chain with more than ten years of experience to meet the unique demands of the medical and healthcare industries, consider working with Seaskymedical. Contact Seaskymedical if you want high-quality medical supplies and equipment to protect patients’ health and safety. Apart from medical device injection molding, Seaskymedical also provides custom plastic injection molding services for other industries, if you are interested in it, feel free to contact us.