The most common technique for manufacturing plastic items in bulk for various applications is injection molding. It can generate simple to complicated components with little waste and is inexpensive and effective. Nonetheless, designing plastic components is a challenging task that takes into account various application-specific aspects.

It is vital to design the plastic mold considering some fundamental guidelines for injection mold part design so that the final products will be stronger and easier to make and assemble. The top-notch medical plastic injection molding companies have skilled designers and advanced technology to precisely develop plastic part mold designs.

What Is A Mold And The Industry Situation

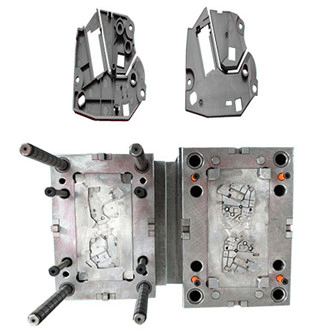

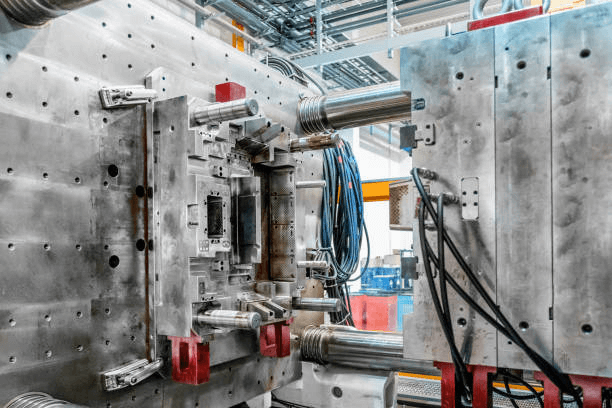

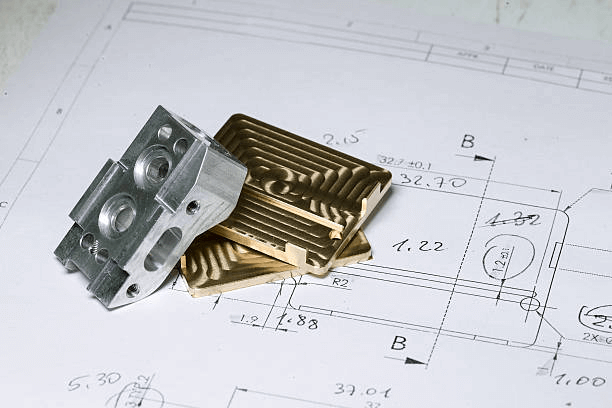

A mold, or tool, is necessary for the injection molding procedure to make plastic components. Custom injection molds are created by mold design engineers, and then skilled mold builders construct the mold for manufacturing. The injection molded item receives a direct transfer of the geometry and surface texture of the mold. To create a high-end mold that can manufacture parts quickly and efficiently, a high level of competence is needed, which is why mold design costs are high.

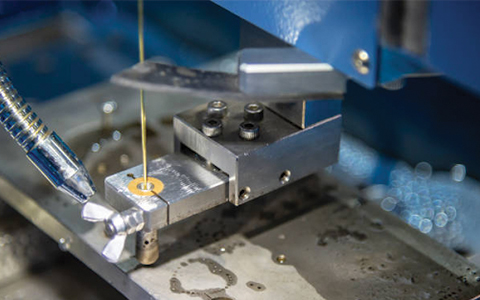

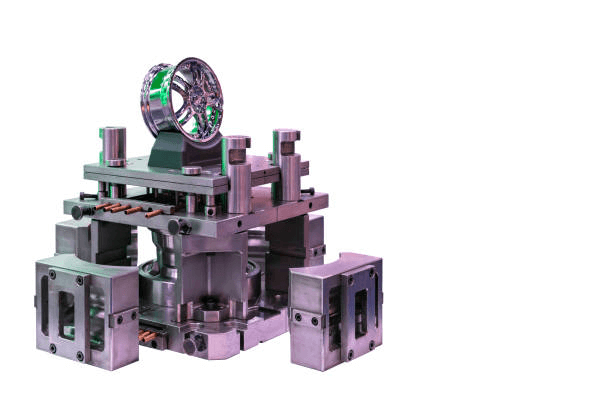

Typically, aluminum or tool steel is used for molds, which are CNC-machined and then completed to the needed standards. The straight-pull mold is the most basic and has two sides, which are the cavity and the core. Retractable side-action cores or other inserts are needed in case of intricate geometries.

The injection molding industry currently represents a $300 billion market, and the number of injection mold medical component manufacturers is rising gradually. Every year, injection molding is used to make more than 5 million metric tonnes of plastic parts worldwide. It is possible to mold any thermoplastic to make plastic components. A few liquid silicones and thermosets can also be used in injection molding. Due to environmental concerns, the demand for biodegradable materials has lately been boosted.

The Importance Of Mold Tooling

Mold design, also referred to as tooling, is a highly technical procedure that calls for an elevated level of technical proficiency. To acquire correct filling and determine the optimum methods for producing tool reliability, tooling engineers and mold designers must make precise analyses of gate sizing. The success of the overall mold-making task is determined by the tooling and mold design.

High-volume and high-quality parts demand the right tooling. To ensure the production of durable, high-quality products, tooling is essential. The design of the tool and the mold is crucial in defining the surface finish. Additionally, regular tool maintenance for injection molding might help in avoiding expensive future problems.

A tool builder is used to develop the final design of medical injection molders. In addition to creating tool designs, mold building requirements are reviewed. The initial samples are created once the molding procedure and the parameters have been defined. When the samples are accepted, the tool construction is confirmed and documented for use in subsequent manufacturing.

Components Of A Plastic Injection Mold

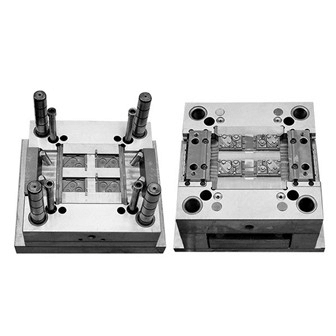

A clean room injection moulding machine has a set of components that lets molten plastic substances be constructed and cooled down to manufacture an item. The components are located on two sides, which are the cavity side and the core side. The cavity side is the stationary side, which contains a sprue, guide pin, cavity, locating ring, clamp slot, camp plate, and cooling channel. The core side is the moving side where the ejector pin, core, ejector retaining plate, clamp slot, and support pillar are there.

Below are some of the primary components of a plastic injection mold.

- Injection Unit

The raw material is to be melted and directed into the mold by the injection unit. The hopper, screw, and barrel make up the injection unit.

- Hopper

Before the injection molding process can start, the plastic material is put into the hopper. For the purpose of keeping moisture away from the plastic material, the hopper typically has a dryer unit.

- Barrel

To allow the plastic to flow down the barrel, the substance is heated in the barrel or material tube until it reaches a molten condition. The clamping unit’s inside screw injects plastic into molds or cavities.

- Reciprocating Screw

The reciprocating screw design has the benefit of assisting in controlling the temperature of the molten plastic substance. The most heat that is applied to thermoforming plastic comes from the reciprocating screw.

- Nozzle

The nozzle is fixed at the ejector system’s bottom section and is another vital injection molding component. It forces the liquid plastic into the mold from the barrel.

- Cavities

The components are molded to the required shape in the mold’s cavities. Molds should be balanced; hence a set number of cavitations is normally permitted.

- Ejector Pins

On the injection mold’s B-side, there are extraction pins that force the produced item out of the mold. Ejector pins come in a variety of designs.

- Clamp Plates

The clamp plates secure the mold halves to the molding platens. Other machines utilize magnets to hold the mold onto the platen, while mold clamps employ huge bolts to hold them in place.

- Guide Pillars

By utilizing guide pins and guide bushings, the cavity and core mold halves are guaranteed to be in the right alignment during mold closing.

- Heaters

The molding substance in the hopper can be melted and turned into liquid by attaching a heating element to the barrel. Coil heaters, cartridge & strip heaters, band heaters, and insulated fabric heating jackets are a few of the several types of injection molding heaters.

Considerations When Carry Out Plastic Mold Design

The procedure of designing a plastic part that needs to be manufactured comprises multiple considerations that touch on all facets of mold design, tooling, choosing materials, and manufacturing. The flexibility of the injection molding technique necessitates far more extensive design considerations. Below are some of the most crucial considerations for mold designing, followed by all injection molding companies.

- Wall Thickness And Radius

The performance of thin or thick part designs might be impacted by jagged shrinkage. The recommended corner’s thickness should fall between 0.9 and 1.2 times the part’s nominal thickness.

- Tolerance

The shrinkage that takes place while cooling has an impact on tolerances. In general, semi-crystalline polymers such as PEEK include looser tolerances compared to amorphous materials such as PLA.

- Gate Location

To ensure that the plastic substance flows into the mold properly, gates are essential. The kind of gate and where it is placed have a big influence on the item’s overall quality and appearance.

- Draft Angle

The item may not discharge from the mold or come out damaged if there is no draft. Draft angles between 1° and 2° are typically needed, but they can change based on part constraints and specifications.

- Reinforcing Ribs

Ribs can be put into parts to assist in keeping them in form and function. It is vital to consider the issues of thickness, sink, and draft in these locations as well.

- Materials

Select the materials for the mold design considering the industry and application. The desired tolerance level or specific attributes, such as wall thickness, can be impacted by the material choice. Only premium raw materials are used by high-end injection mold companies.

- Mold Shrinkage

The shrinkage that takes place during the molding of plastic parts might reach 20% of the original volume. The most vulnerable materials to heat shrinkage are crystalline and semi-crystalline materials.

- Surface Finishes

Depending on the purpose of the part, many surface finishes may be possible. The amount spent on mold creation directly depends on whether a shiny, textured, or machined finish surface is required.

- Undercut Features

Undercuts are features that a part needs if it requires to be prevented from getting ejected from the core and mold cavity. It will be highly economical to develop and build the mold if the design can be changed to remove those elements.

- Datums

Establish component interfaces and interactions with the overall system using datums. Utilizing a datum structure that is consistent with the assembly’s design intent can make the difference between a product working properly or not.

Injection Mold Engineering Cores

The plastic injection molding engineering solutions are highly suitable for custom designs and 3D mold prototyping. The injection mold engineering cores are described below in detail.

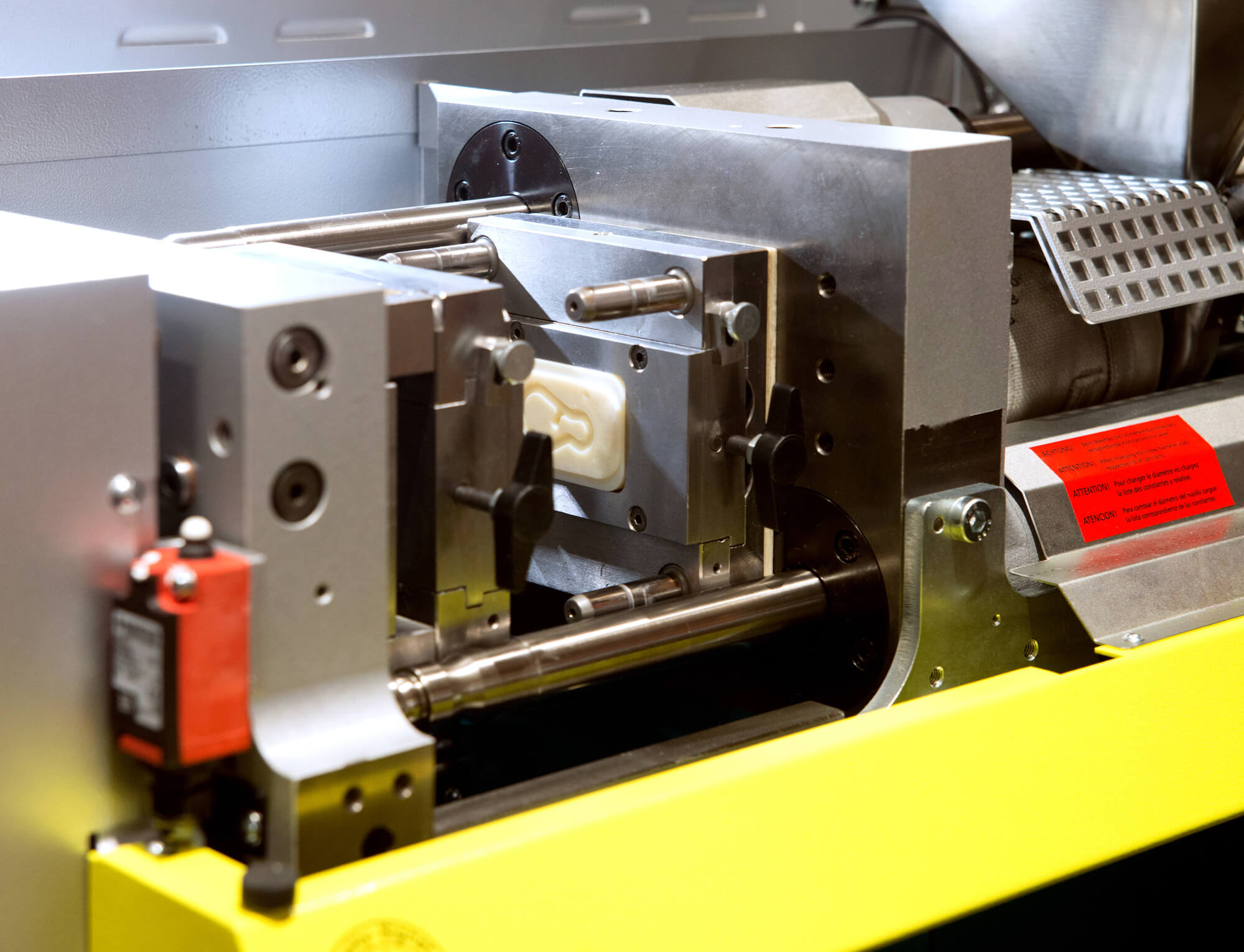

- Ejection System Design

The instruments are firmly fastened together throughout the injection procedure. The tool unlocks after the plastic has cooled down enough to keep its shape, often by the core and portion moving rearward away from the cavity. The part is then forced by ejector pins through the core and away from the tool, allowing it to fall free.

When the component has finished cooling, ejector pins force them out of the mold and almost always leave a mark. These are generally discharged onto surfaces of parts that are not always visible. The surface on which the ejector pin pads will be mounted must be perpendicular to the direction in which the ejection pins will press.

There will be some witness markings left on the part as a result of this procedure. For instance, where the two parts of the mold come together, there will be separation lines. Where the pins connect with the part, there will also be ejector marks visible. However, these are typically concealed on the back.

- Gate Design

The molten plastic enters the cavity through gates. The flow into a portion is controlled by the geometry and position of a gate. The gate attaches the part to the runner system. The part geometry, mold structure, and material selection all influence the gate’s layout.

Gates ought to be placed away from locations with a lot of tension or impact. The gate must be placed where it will fill the section properly, which is often where it is thickest. It is better to remove secondary de-gating in gate designs. Based on the size of the plastic part, geometry, and material choice, numerous gates may occasionally be required.

There are numerous sorts of gating techniques. The aesthetic and dimensional criteria of the finished product will also affect the gate’s design and type. The most popular gates are edge gates, which inject at the portion line where the two mold halves converge. After ejection, the runner system is physically withdrawn, leaving a faint witness mark.

Under the dividing line, tunnels or sub-gates are injected. Runners do not need to be manually extracted because they are snapped off after ejection, which is suitable for large-scale production. Large-scale manufacturing needs a better quality management system and should follow stringent inspections. For runner systems, direct gates attach from the spur to the top of the portion to minimize material waste. Even though it is suitable for bigger parts, there will be visible marks.

The hot tip gate is the one that is more popular among the hot runners types. Hot tip gates are perfect for circular or conical shapes where consistent flow is required and are often situated at the top of the part rather than on the parting line. Pin gates are preferred for aesthetics because they inject material from the interior of the part in the Core or “B tool” out from the visible exteriors.

- Runner Design

Through a series of passages in the tool known as the runner system, molten plastic enters the component. It manages the pressure and flow at which the liquid plastic is infiltrated into the cavity and expelled out of it. Gates, sprue, and runners are the primary three parts of this.

The sprue is the primary route through which all the molten plastic initially runs through as it penetrates the mold. The runner joins the spur to the gates by spreading the molten plastic along the face where the two sides of the mold converge. After ejection, the runner system is disconnected from the component. The gate serves as the material’s point of entrance into the mold’s hollow. Its geometry and position are crucial because they affect how the plastic flows.

- Cooling System Design

While producing medical injection molding parts, cooling often takes up to 50 to 75% of the cycle duration, so it needs to be properly managed. Additional chilling time may drastically lengthen manufacturing and cycle times. Traditional cooling and conformal cooling are the two primary types of cooling used in injection molding. Each type is based on the fundamental idea of cooling channels that allow a cooling agent to pass across them.

Regardless of the approach being used, there are a number of critical elements to take into account when designing a cooling system. Verify that the cooling channels are situated as close to the thickest area of the mold cavity as possible. It is better to have several smaller channels than one bigger channel. The mold’s bigger cooling channels must maintain a constant diameter. To improve cooling, take heat transfer into account when choosing mold materials.

- Wall Thickness

Using a constant wall thickness and utilizing as few wall sections as possible when developing a plastic part is another crucial requirement. Injection molding is facilitated by uniform walls, which also lessen the possibility of sink marks, differential shrinkage, and molded-in tension. Additionally, high-end injection mold companies save up costs by minimizing wall sections and ensuring they are uniform.

Because smaller walls let parts cool more quickly, cycle times are shorter and more parts can be produced each hour. An injection mold part’s wall thickness should typically range from .060″ to.180″, but parts can be formed with walls as thin as.020″ and as dense as 1.50″. However, one should remember that thick sections on a component will also result in cosmetic problems like bubbles, sinks, discoloration, etc.

The wall thickness of parts should be uniformly designed, which makes it simpler and more unrestricted to fill the mold cavity. Additionally, if the wall thickness is uneven, thinner areas will cool first, followed by thicker sections, which will cool and contract, creating strains close to the boundary between the two. The thinner parts do not generate since they are already cemented.

When the thicker sections give way, it results in warping or twisting, which will lead to fissures in drastic cases. For non-uniform walls, the change in thickness must be gradual and shall not surpass 20% of the nominal wall. Selecting the right wall thickness for a part can retain a significant impact on price and production efficiency. Thinner walls need less substance, which lowers cost and cools more quickly, shortening cycle duration.

Injection Mold Design Process

The injection mold design process is quite complex since many critical aspects have to be considered. Even slight miscalculations can lead to huge production problems and excessive costs. The detailed injection mold design procedure is listed below.

- Analyze The Plastic Part

To establish the product specifications, mold design engineers, tooling engineers, materials makers, production engineers, quality engineers, and lab technicians will collaborate. The final plastic part will be analyzed to know the certain mold requirements.

The experts pay close attention to any prospective part geometry or tolerance issues that could lead to inadequate steel conditions or necessitate the use of specialized tooling features like slides, lifters, threading, unthreading, etc. To pick the appropriate mold steel and consider mold cooling, the physical and chemical characteristics of the chosen material are also assessed.

- Design For Manufacturing

The custom plastic injection molding manufacturers develop and create the mold precisely for the component they will be producing. Mold designing for manufacturing is crucial, whether for creating a new part, upgrading an existing one, or altering the manufacturing procedure.

If one does not consider the manufacturing process when designing a component, there may be significant short-term and long-term timing repercussions and heavy costs. So, it is vital to design a mold part that is compatible with being manufactured without any potential issues.

- CAD

Modern motion simulation tools offer designers the advantages of an accurate visual representation of the kinematics of the mold as well as thorough collision detection, including automated identification of mold parts. The CAD package comprises tools or modules that allow you to create and see a complete model of the mold, including creating the core and cavity from the component model.

CAD tools for mold design are getting better at defining and examining some of the most important features of the mold model, like the development of parting lines, core and cavity geometry, parting surfaces, etc. Utilizing software for 3D solid modeling or surface modeling or applications that combine both types of capabilities in one program, mold designers can develop their tool models.

- Mold Flow Analysis

Mold flow analysis is a tool for predicting how a particular plastic will behave in the mold. A particular plastic and part design are used in the simulation of an injection molding cycle by mold flow analysis software. Designers can assess a material’s qualities via mold flow analysis, including its cooling capabilities, shrinkage rate, the possibility for aesthetic defects, capacity to fill cavities, etc.

To show how the plastic would behave in the mold, the study produces colored reports. Average temperature, fiber orientation, knit lines, sink and warp, air traps, fill confidence and fill time result are some of the reports. The designer looks for flow paths that end and reach the edges simultaneously. Consistent shapes show how quickly the plastic is moving. Narrow contours suggest a gradual filling process, while broadly spaced contours demonstrate a quick flow.

- Design Confirmation And Mold Building

To ensure that the mold will create the component correctly, with an adequate finish, dimensional correctness, and in compliance with specifications, the designers and engineers will compare the mold drawing to the plastic part drawing. They will thoroughly confirm the mold design details with the drawing and application-specific requirements to proceed with injection molding.

To select mold sides and steel sizes, initial 2D and 3D design models are built. To determine whether the plastic mold part satisfies the criteria for operation, resilience, beauty, and reliability, expert designers will evaluate the mold design with CNC machined, 3D printed, and urethane cast prototypes. The completed detailed design is produced after they have been examined and accepted. Many manufacturers perform injection molding in clean room that is equipped with advanced molding machines.

Conclusion

The favored method for delivering mass-produced plastic parts for all industries is plastic injection molding. In order to acquire high-quality and high-precision plastic mold parts, mold designing is one crucial aspect. To ensure proper plastic part mold design and tooling, it is best to contact a reliable plastic injection molding company.

At SeaskyMedical, there are experienced plastic injection mold designers and engineers who will develop customized plastic mold tooling as per the application-specific and client requirements.