Having the necessary information will prevent you from making a huge mistake when selecting the injection mold maker that will design the mold for your plastic equipment manufacturing. A mold can be quite complicated to design and costly, which is why it’s a huge investment that mustn’t be made without the appropriate information.

In this post, we will highlight all the information you need to make the best decision when selecting your preferred custom plastic injection molder, as well as top 5 injection mold makers best for your business.

What is Plastic Injection Mold Making

Plastic injection mold making is simply the fabrication of molds that are used to produce plastic parts. It’s a complicated process that requires the use of tough materials like steel and sometimes stones.

Following the design of the plastic part to be produced, the professional mold maker will manufacture the mold to be able to replicate such design. For instance, the mold used for plastic medical components manufacturing must be designed according to the shape of the medical device part. This means that a plastic mold maker will have to make different molds for syringes and drug containers.

Most molds are made of hardened steel and they are fabricated to be strong and resistant to all kinds of elements, including chemicals and harsh temperatures. No matter the pressure they are put under, they don’t degrade. The mold is used to produce high volumes of plastic parts, which is why they are designed to be extremely tough and durable in order to function effectively for a very long time.

Importance of Mold Making

Mold making is an integral part in the injection molding process that provides an impressive number of benefits. Some of them are:

- Precision and Accuracy: While there is always a high probability to make mistakes with plastic parts production, custom molds ensure that the manufacturing process is smooth and the plastic part comes out in the exact form envisioned. No specification will be compromised; not even the shape, weight, tolerance, etc.

- Strength: One of the responsibilities of a mold maker company is to fabricate a durable mold that can last the test of time. Since the mold is strong, it can be used to make continuous production without incurring extra costs of making a new mold.

- Fast Production: Custom molds enable plastic part manufacturers to produce freely without doing any guesswork. This allows for high-volume production within a short time.

How to Make Mold Tooling

Basically, there are three steps used by injection mold makers to create appropriate molds. They are:

- Create a CAD File of Your Idea: The first step is to create a computer-aided design of your mold, including all the specifications necessary. After the design is completely sorted out, a prototype of the plastic part and mold will be made to confirm the reliability of the design.

- Form a Prototype from the CAD: Using 3D printing, create a prototype of your mold design to confirm if production is feasible or not. 3D printing is used because it’s less-costly compared to creating an actual mold as a trial. With it, any design or engineering flaw can be resolved before creating the final mold.

- Create the Mold: After all the flaws are sorted out through 3D printing, take your metal material and begin to fabricate the mold according to the mold design. Even at this stage, mistakes can still be made, which is why it’s essential that you employ the service of a professional mold maker.

What Areas are Plastic Mold Making Best Applied To

The application of plastic mold making is vast, ranging from intricate parts, and hard-to-design parts, to simple products. Some of the areas where the application is common are:

- Medical devices part

- Automobile parts

- Household appliances

- Farming equipment

- Beauty tools

- Housings for electronics

- Packaging and containers

5 Recommended Plastic Mold Makers for Your Business

Below is the list of the best plastic mold makers that can help with your business needs. This list was curated based on their business information, track records, certifications, as well as products & services offered.

- Seaskymedical

- RYD Tooling

- Artemis Plastics

- Sanpac Africa

- Transumanoleader

1. Seaskymedical

- Business Type: Custom Injection molding manufacturer

- Headquarters: Shenzhen City, China

- Year Founded: 2008

- Key Product: automobile parts molding, medical device parts, and others

Seaskymedical focuses on the development and production of plastic injection molded devices. Serving as one of the best medical plastic manufacturers in the world, they offer one-stop service, starting from mold design to the production of all plastic products.

Over the years, the company has continually provided high-grade injection molding service that complies with the industry standards and has obtained certifications from the FDA, ISO, and many others. Seaskymedical practices Class 8 clean room injection molding, manufacturing all their molded products in a safe and healthy factory that’s contaminant-free.

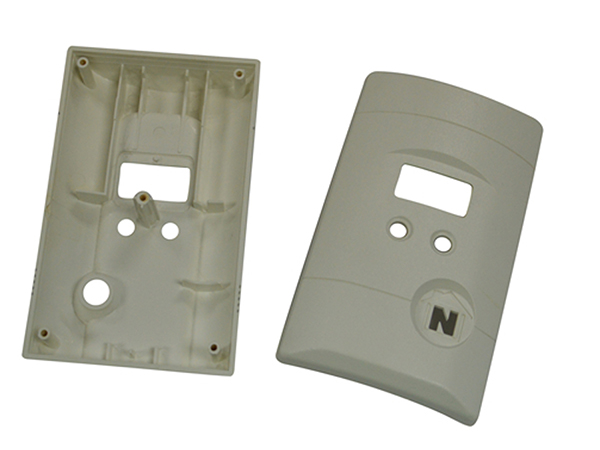

2. RYD Tooling

- Business Type: Plastic injection molding manufacturer

- Headquarters: Shenzhen, China

- Year Founded: 2006

- Key Product: Injection molds

Located in one of the busiest places in China, RYD Tooling produces precise injection molds that are used for manufacturing numerous pieces of equipment in the electronic and automotive sector. Making use of cutting-edge technologies like the CNC machine and EDM machine, the company’s production process is very fast.

Thanks to their highly-skilled workforce, the company combines technology with the expertise at their disposal to make injection molded parts from scratch to finish.

3. Artemis Plastics

- Business Type: Injection molding manufacturer

- Headquarters: Ocala, Florida

- Year Founded: 2011

- Key Product: Medical device molds

Serving as a medical injection molded manufacturer and offering assembly services, Artemis Plastics stands out from other medical molding companies for meeting the complete needs of the healthcare sector.

Their expertise extends to designing health product tooling, prototyping, production, assembly, and secondary operations. The company is known home and abroad for its medical device injection molding expertise, which has given them several awards like the Florida Sterling Manufacturing Business Excellence Award 2019 and GrowFl 2018.

4. Sanpac Africa

- Business Type: Injection molding manufacturer

- Headquarters: Mombasa, Kenya

- Year Founded: 1972

- Key Product: Injection molds

Sanpac Africa started as a small company that manufactures sanitary napkins until they invested in the injection molding industry, which opened up more opportunities. Currently, the company has evolved as the leading injection mold maker in the Africa region, thanks to the adoption of robotic technology.

Sanpac Africa is home to more than 250 workers who have various skills that contribute to the production of quality plastic parts. Their products are in high demand globally, with both domestic and commercial industries benefiting from their excellent service.

5. Transumanoleader

- Business Type: Injection molding manufacturer

- Headquarters: Lisbon, Portugal

- Year Founded: 1972

- Key Product: Injection molds

Transumanoleader was initially created as a distributor of products until it was acquired by a new owner who scaled it up to become an injection molding company. The operation process is handled by a group of highly-trained professionals who are deeply invested in research and technology.

They produce injected molded parts for the automotive industry, aerospace industry, food and beverage industry, as well as carry out injection molding in a clean room for the medical industry.

How to Choose the Right Plastic Mold Maker

Choosing the right plastic molding maker from the wide range of plastic molding companies on the market is a crucial decision that is influenced by a number of factors. These factors are:

- Mold Construction Requirements

You need the injection molding details, such as the number of parts that will be produced at once and know the long-term production goals. This will determine the number of cavities the mold will have. Although a mold is generally summarized to have “two halves”, a cavity side and a core side, there are numerous precision parts that make up each half. Select a mold maker that can replicate your mold construction requirements.

- Mold Design

The design of the mold has a large impact on its cost. The process requires a lot of pressure when the plastic is injected into the mold cavities. Without these high pressures, the molded parts won’t come out with smooth surface finishes and will not be dimensionally correct. So the mold must be designed with tough materials that can withstand the pressures. Your preferred mold manufacturer should be vast with different design patterns and the conditions that coke with them.

- Mold Materials

Understanding your material specifications is essential. The mold maker should recommend the best type of plastic material for your injection molding application because many types of plastics will need to be molded in tools made of certain types of metal. For example, parts made from propylene can be made with light metal molds, but polycarbonate is a very rigid material that takes more time to melt, meaning that it must be used in a hard metal mold that can resist heat.

- Lifetime Warranty of Mold Tooling

Another cogent factor you need to consider is the production life of the mold. Choose an injection mold maker that guarantees renewal or some sort of compensation in case the mold stops functioning within a short time. The tooling cost used in making molds are expensive so it’s only right that there is some warranty attached.

FAQs

Injection Molding Processes

Plastic injection molding process needs three major components – an injection molding machine, a mold, and plastic resin (thermoplastic or thermoset). Below is a very brief explanation of the injection molding process.

- Step 1: Clamping

The injection machine closes the two halves of the mold with a high force, preventing it from opening when injecting the plastic resin.

- Step 2: Injection

Raw plastic material, usually in the form of small pellets, is injected into the molding machine at the feed zone. As the plastic material flows through the heated zones of the machine barrel, it heats up and compresses.

The amount of melted plastic that’s transmitted to the front of the screw is a strictly controlled dosage as that will be the amount of plastic that will become the final part after injection is finished. As soon as the melted plastic reaches the front of the screw and the mold is fully clamped, the injection molding machine transfers it to the mold, pushing it into the endpoints of the mold cavity under high pressures.

- Step 3: Cooling

Once the molten plastic reaches the internal mold surfaces, it begins to cool. The cooling time for each plastic molded part is different as it depends on the thermodynamic properties of the plastic, the part’s wall thickness, and the part’s dimensional specifications.

- Step 4: Ejection

When the part is cooled inside the mold and the next part process is about to begin, the machine will unclamp and open the plastic injection mold. At this stage, the molded part is pushed out of the mold.

Why is Injection Mold Tooling Cost So Expensive

Manufacturing good plastic parts can only be achieved by using high-quality built molds. And this doesn’t come at a cheap price as several costly components are involved.

- Material: The plastic part may be small, but the mold is usually large and heavy. They can weigh as much as 300-500 lbs and even thousands of pounds. Acquiring this amount of metal is expensive.

- Number of Cavities: Depending on the volume of parts to be produced, you may need a high cavity tool. One cavity can only produce one part each time the mold cycles. More cavities lead to more parts per cycle. Including more than one cavity in the mold design results in a higher cost.

- CNC Machining: Every mold is a custom design. Machining the cavity, cooling lines, ejector pins, and system must be accurate and within tolerance. With technologies like the CNC machine, mold production time will be reduced and better precision will be achieved.

- Part Features: Plastic part features like undercuts will require slides or lifters, which adds to the mold production cost. Surface finishes also contribute to the increase in mold cost.