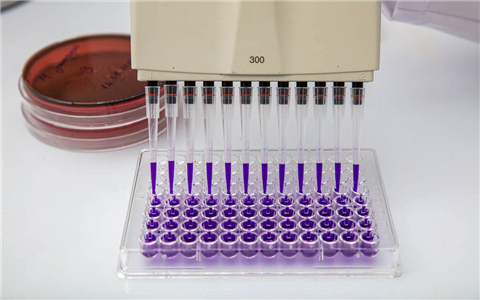

As minimally invasive surgery development, there is more and more demand for thin wall micro medical plastic parts. Once the wall of plastic parts is less than 1mm we call is thin wall molding. But for micro plastic parts thin wall demand is much less than 1mm, sometime the products need to be 0.1mm.

You can review below video for our micro plastic molding.

Challenge of micro medical plastic molding

Except for the thin wall of plastic parts is difficult to reach on injection molding. Also most of micro plastic parts is less than 1g, sometime it is 0.01g. Most micro products start with some extreme challenge. Micro components are becoming increasingly complex because they need to be installed in small, delicate arteries, pumps, catheters or endoscopes, possibly with working micro components inside. They are often geometrically challenging because they were once designed as two or more components, but were reduced to a single component under cost pressure so that they did not have to be assembled under a microscope.

Since precision of micro-injection molded products is often in the range of several microns, there are several challenges in achieving good dimensional repeatability in injection molded parts. It’s one thing to create beautiful sharp corners and cavities in mold steel (with a radius of less than 1 micron), but it’s quite another to fill these tiny spaces with polymers. Micro molds require proper venting, sometimes using very thin gap to achieve proper venting and sharp filling.

Solution

Expect for precise mold manufacture, SeaskyMedical also have micro injection machine to run micro plastic parts. As said above, most micro products start with some extreme challenge, to understand the demand, function and requirement is first step to achieve success for micro plastic molding. So both of us on the same page on sharp edge, polishing area, non-polishing area and tolerance. We are willing to work together with you to develop micro plastic parts.

On micro plastic molding, the gate size, runner size, draft and venting even it is mold plate thickness is totally different as the common precise injection mold.