The medical equipment itself has strict precision properties. Therefore, more precise technical requirements are put forward for medical devices production. In the supporting medical parts production such as hyperbaric oxygen chamber, hearing aid, anesthetic laryngoscope and medical button, there is strict requirement on surface quality, precision and hygiene requirements for injection molding parts.

Medical disposable anesthetic laryngoscope is the most typical and complicated injection molding product in many medical products.

Challenge

Medical disposable anesthetic laryngoscope blade complexity is mainly reflected in the following aspects:

- The product structure is complex and the top space is narrow.

- The top tip touches the skin inside the body, and the material hygiene requirements are strict.

- Strict size and quality requirements, no surface defects allowed.

- Injection molding products laryngoscope is generally a disposable product,

- Large quantity and price cost requirements within the control range.

Solution

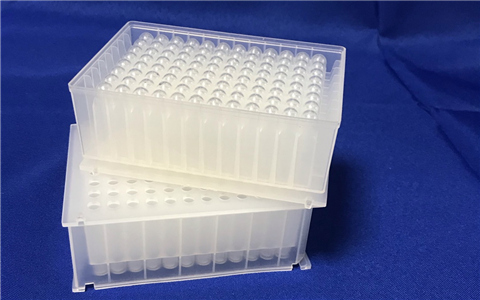

High quality mold with high capacity is one of first step to meet your demand. To reduce the shot time and nice surface finish is important for medical disposable anesthetic laryngoscope blade.

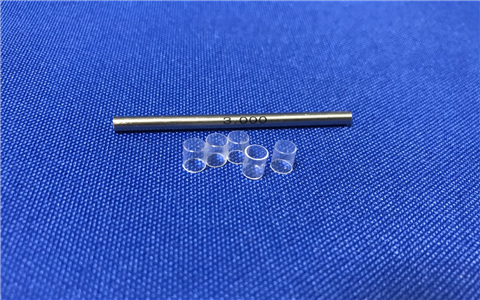

Waterway system is one of the important factors of molding product quality, superior waterway system can shorten the molding cycle and improve the yield of products. We use 3D printed water line to assure the core of plastic blade mold is cooled consistently and fully. Also the surface finish is quite better to control than the traditional cooling, especially on the lens area.