Custom Various Polypropylene (PP)

Molding Services

Undoubtedly, Polypropylene is a strong material with decent enough resistance to wear and tear. There are different types of Polypropylene molding services that we are providing at SeaskyMedical.

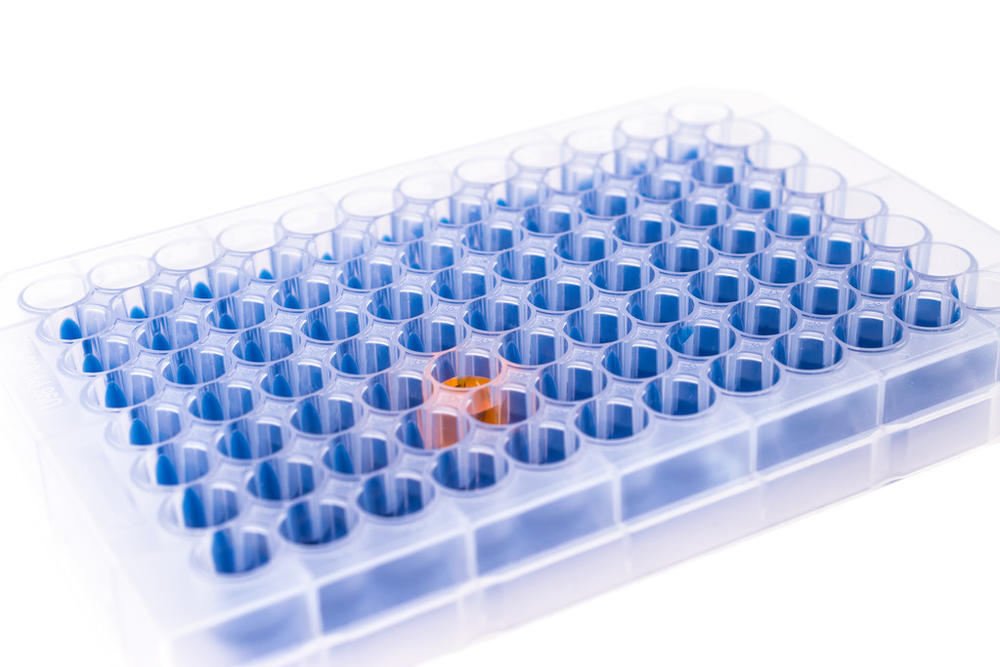

Medical Injection Molding

Medical device injection molding is a cost-effective and efficient method of producing medical items, equipment, medical device assembly line models, and autoclavable labware with high levels of precision, accuracy, and quality.

Medical Overmolding

Overmolding is another type of PP injection molding procedure where two or more parts of the same or different designs are clipped jointly. Plastic overmolding is done by utilizing heat and pressure apart from liquid silicone.

Insert Molding

Medical Insert molding is the method of molding or constructing plastic parts close to the plastic parts. With this process, both simple and complicated PP molded components can be inserted.

Medical Micro Molding

Micro molding is a procedure for producing plastics elements for shot weights (1 to 0.1 grams) with 10 to 100 micron tolerance. This helps in the creation of high-quality, better-precision, and micron-tolerance thermoplastic components.

Ultrasonic Bonding

Ultrasonic molding or ultrasonic microinjection molding is one of the latest technologies provided for our clients. This process utilizes high-power ultrasound to soften and mold thermoplastic polymers to generate varieties with mini and micro-features.