Micro injection molding is becoming very important in making medical equipment these days. For example, in 2020, the companies in the United States that make things out of plastic by injecting it into molds made $11 billion. This shows that it’s really important, especially for health-related products. The market for making really small molded parts is expected to get bigger each year by 7.9% all the way until 2026. This is because as medical tech gets better, there’s more need for tiny parts that are made very precisely, which is what micro injection molding services does. These tiny parts are super important for making things like medical tools that go inside the body and systems that deliver medicine, where it’s super important to be exact. It’s all about making big improvements in healthcare by using really small parts. When we look at the companies that are leading in this area, it’s important to remember that the goal isn’t just to make smaller things—it’s to think in new and bigger ways about the future of healthcare. Now, we’re going to talk about some of the micro injection molding companies.

List of Top 5 Micro Injection Molding Companies

- SeaskyMedical

- Makuta Technics Inc.

- Accumold

- Stamm AG

- Sovrin Plastics

#1 SeaskyMedical

Location: Shenzhen, China

Established: 2008

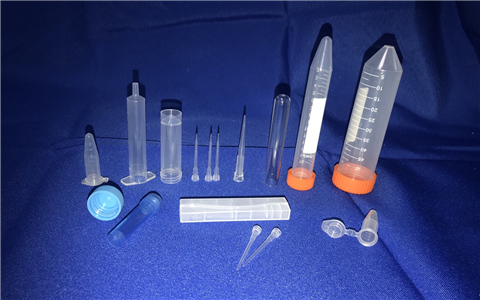

In the highly specialized sector of plastic injection molding, SeaskyMedical, situated in Shenzhen, China, stands at the forefront as a premier provider of bespoke plastic injection molding solutions. Established in 2008, the company has distinguished itself within the medical sector by concentrating on the production of micro-components for medical devices, including advanced packaging solutions—a significant achievement of high quality precision engineering.

SeaskyMedical is acutely aware of the critical nature of their work in micro injection molding, where precision is measured in microns, particularly within the healthcare arena. Their portfolio boasts the creation of diminutive parts, some weighing as minute as 0.1 grams, showcasing a remarkable fusion of artistic craftsmanship and scientific prowess. They have mastered the production of components with ultra-thin wall thicknesses of up to 0.2 mm, showcasing their capability for tight tolerances and advanced engineering.

The defining feature of SeaskyMedical’s distinction is their unwavering dedication to innovation coupled with rigorous quality control. Their integration of an ISO 8 cleanroom and advanced machinery from Japan and Germany is indicative of their commitment. Beyond the hardware, SeaskyMedical’s overmolding techniques significantly enhance the functionality and longevity of medical devices, ensuring they are ergonomic, efficacious, and safe.

SeaskyMedical’s ascent in the micro injection molding field is underscored by their profound comprehension of client requirements. They are dedicated not merely to manufacturing components but to forging vital solutions that cater to both client satisfaction and the health and safety of patients. From conceptual design through to production, their operations adhere to the most stringent standards of excellence and precision, cementing their status as a vanguard in the realm of custom plastic injection molding services.

Their steadfast focus on quality and continual innovation has earned SeaskyMedical a reputation as a reliable collaborator in the medical industry. Their contributions transcend the boundaries of commerce; they play a pivotal role in the advancement of healthcare, positively affecting lives with each micro component produced. As the industry progresses, SeaskyMedical remains a paragon of exceptionalism in micro molding services.

#2 Makuta

Location: Shelbyville,IN

Established: 1996

Makuta Inc. stands as a paragon of professionalism within the micro injection molding industry, continuously raising the bar for precision and exceptional craftsmanship. As pioneers in the realm of micro-molding and advanced micro mold tooling, Makuta Inc. demonstrates an unwavering commitment to quality, transforming the fabrication of minute components into a meticulous symphony of detailed precision and strict tolerances.

Within the high-criticality realms of the medical and pharmaceutical sectors, the technical virtuosity of Makuta Inc. is incontrovertible. Harnessing cutting-edge technology, Makuta Inc. consistently achieves dimensional tolerances as stringent as ±5 microns, far exceeding industry norms to produce components that are the epitome of flawlessness. This rigorous dedication to impeccable production assures the realization of zero-defect parts, an indispensable criterion within these highly regulated industries.

Makuta Inc.’s competitive advantage is further enhanced by the strategic implementation of Sumitomo’s all-electric injection molding machines, epitomes of efficiency and pinpoint accuracy. These machines epitomize the fusion of optimized energy consumption and refined cooling processes, enabling expedited production timelines while delivering products of unparalleled quality. The facilities at Makuta Inc., a concrete manifestation of their relentless quest for excellence, operate within ISO-certified cleanroom environments—ideal for their sophisticated molding operations and robotics to forge manufacturing results that are simply superior.

The scope of services offered by Makuta Inc. encompasses a diverse array of client requirements, ranging from high-volume production runs to intricately complex mold designs for consumer commodities. Their expertise in micro-scale precision molding is seamlessly integrated with a suite of ancillary services, including silk screening, variable shot sizes, pad printing, and cutting-edge automation for printing tasks. This comprehensive suite ensures that clients are provided with bespoke solutions that not only fulfill but exceed their exacting standards with remarkable efficiency and unparalleled precision.

#3 Accumold

Location: Ankeny, Iowa, USA

Established: 1985

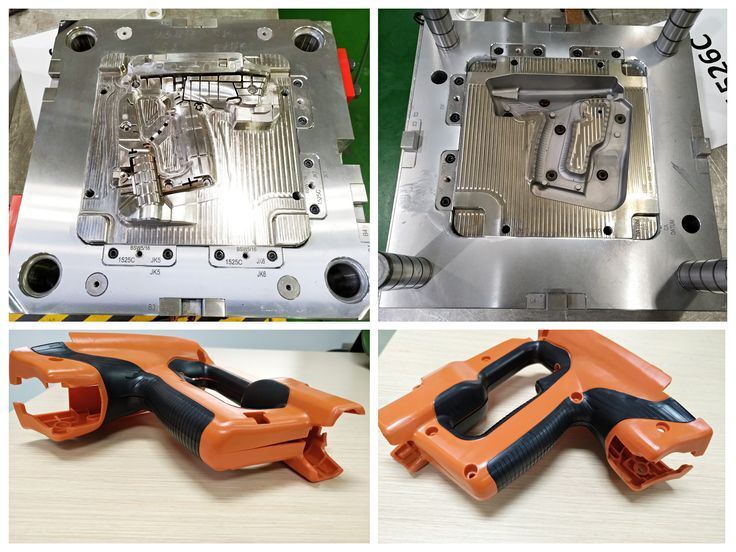

Since its inception in 1985, Accumold has emerged as a beacon of excellence in the micro molding industry. The company commands profound respect for its unparalleled proficiency in producing exceedingly small components. This proficiency is founded on its proprietary Micro-Mold® technology, which ensures the output of injection-molded parts is characterized by supreme precision and expedited production rates. Accumold’s prowess is most conspicuously evident in its creation of intricate components tailored for the medical, electronics, and advanced technology sectors.

Accumold distinguishes itself amid the fiercely competitive market with an unwavering commitment to micro-scale production that does not compromise on ultra-precision. The enterprise specializes in fabricating parts that comply with exacting requirements, with tolerances measured in mere microns. This exceptional ability is facilitated by Accumold’s integrated design and manufacturing framework, which delivers comprehensive oversight throughout the production continuum— a strategic benefit that is imperative when dealing with components of such minimalistic dimensions.

The depth of Accumold’s expertise is not confined to the minutiae of small-scale production; it also demonstrates avant-garde manufacturing insight. This is showcased through their implementation of an advanced dual-material injection molding process executed within a single mold cycle. This technique underscores their forward-thinking capabilities and sophisticated mastery in the micro molding sector. Operating out of Iowa, Accumold is renowned for its congenial and proactive customer engagement, reflecting the genuine warmth and authenticity inherent to its community roots.

At Accumold, quality is not just an aspect of their work; it is the bedrock upon which all operations are anchored. The intricate nature of their products necessitates an extraordinary level of scrutiny, where meticulous craftsmanship meets and exceeds the industry’s most stringent quality benchmarks. Adherence to strict quality control protocols is not merely a regulatory compliance but a doctrine that Accumold abides by.

#4 Stamm AG

Location: Switzerland

Established: 1962

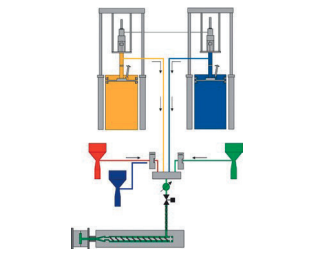

STAMM AG stands as a paragon of innovation and excellence within the realm of injection molding technologies. Our storied heritage, combined with a progressive outlook, positions us as the quintessential partner for bespoke solutions that epitomize precision and superior performance. Our ethos, encapsulated by the tagline “Peak Performance in Plastics,” reflects our unwavering dedication to achieving and sustaining pinnacle quality across diverse sectors.

Our proficiency in precision injection molding is formidable, honed over three decades of dedicated practice in the creation of components with exceptionally fine tolerances and controlled shot weights. We consistently produce parts with exactitudes down to ±0.01mm and a weight spectrum ranging from a mere 0.01g to 150g. In the realm of micro-injection molding, our prowess is unequivocal—we reliably manufacture components in vast quantities that defy conventional weight limitations, venturing into the microgram range.

Moreover, STAMM AG’s capabilities extend beyond the miniature. We excel in the fabrication of hybrid components, ingeniously merging disparate materials to forge multifaceted solutions that serve both aesthetic and functional purposes. Our expertise in multi-component molding is unparalleled, featuring sophisticated technologies such as rotary tables, index plate systems, and core-back processes, all meticulously customized to fulfill the intricate requirements of our clientele’s tooling needs.

#5 Sovrin Plastics

Location: Slough, Berkshire, UK

Established: 1967

Established as a paragon within the realm of injection molding, Sovrin Plastics heralds over half a century of unmatched expertise. Their unwavering fidelity to precision permeates their specialized endeavors across the medical, electronics, and engineering sectors. As custodians of quality, Sovrin Plastics delivers a full spectrum of services that adeptly bridge the gap between innovative conceptions and the realization of superior-quality products.

Central to Sovrin’s corporate philosophy is the rigorous application of the lean 6 sigma principles, a clear indication of their unyielding commitment to operational efficiency and unparalleled quality standards. Fortified by a formidable contingent of 140 dedicated specialists and an arsenal of 52 cutting-edge molding apparatus, Sovrin stands at the forefront of fabricating intricate components. This is particularly pronounced in their pivotal role within the healthcare industry, a domain where they have been instrumental for over thirty years. Sovrin’s acumen is particularly pronounced in areas demanding acute precision, such as state-of-the-art drug delivery systems and sophisticated diagnostic apparatuses, which are essential to public health infrastructure.

Sovrin’s production operations are meticulously executed within the controlled environs of Class 7 & 8 Cleanrooms, a stringent measure that ensures the utmost cleanliness indispensable for medical-grade product fabrication. As vanguards of technological advancement, Sovrin embraces pioneering materials, including bio-absorbable and conductive polymers, to catalyze innovations in medical and electronic product development. This relentless pursuit of excellence is underscored by their integration of an advanced inline optical comparison system, a hallmark of quality assurance leadership within the industry.

Conclusion

When engaging a partner for micro injection molding, the emphasis on precision cannot be overstated. Leading entities in the domain boast cutting-edge machinery that fabricates components conforming to the most stringent criteria. Entities like SeaskyMedical, which are outfitted with sophisticated micron-level precision apparatus, guarantee extraordinary exactness for intricate components. Their team’s proficiency in maneuvering a plethora of materials, ranging from conventional plastics to bespoke resins, underscores their adaptability to cater to the multifaceted requisites of various industries. In realms such as medical device fabrication, where the sanctity of cleanliness is non-negotiable, these firms typically operate in cleanrooms. These environments are meticulously aligned with rigorous regulatory benchmarks to maintain manufacturing sterility. Opting for such a partner provides clients with a fluid progression from conceptual design to full-scale production, underpinned by a commitment to excellence and meticulous attention to detail.