The world of manufacturing is filled with various techniques designed to create high-quality, durable products. One such technique, which has gained significant popularity in recent years, is liquid silicone rubber (LSR) injection molding. This technique has transformed the production of versatile parts for industries ranging from healthcare to electronics, providing high quality and durable products.

Liquid Silicone Rubber is a high-quality performance elastomer that exhibits phenomenal resistance to extreme temperatures, including a wide range of temperatures, weather conditions, and water. Its unique properties make it an ideal choice for an array of applications, particularly those requiring durability, flexibility, and biocompatibility in medical applications, elastomers.

LSR injection molding is a robust and versatile technique that leverages the distinct qualities of liquid silicone rubber injection molding to create a variety of parts with complex geometries. The process utilizes a closed-loop system, which enhances the production efficiency and minimizes the chances of contamination, a critical aspect for industries like healthcare, where hygiene is paramount. Liquid silicone injection molding is a popular method used in the production of medical devices, automotive parts, and consumer goods (here’s a guide of how it works).

The Process of Liquid Silicone Rubber Molding

The LSR injection molding process is a multi-step journey that transforms raw silicone into a finished product. Here’s a step-by-step walk through of the process:

Mixture Preparation

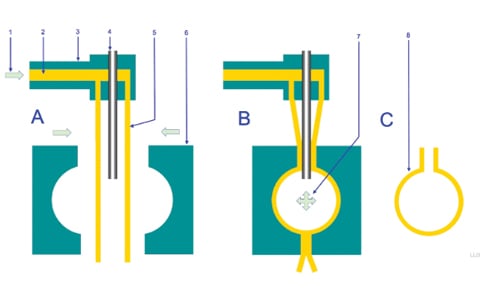

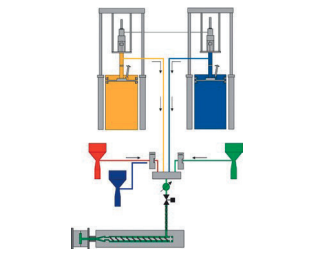

To ensure the proper performance and characteristics of the final product, the liquid silicone rubber mixing process is prepared by accurately measuring and mixing two components – the base silicone and the catalyst. In addition, pigments and additives, including pigment, can be added to achieve specific color or enhance the material’s properties. The mixture is carefully homogenized to ensure uniform distribution of components throughout the silicone. Temperature stabilization systems can also be utilized to control and stabilize the temperature of the silicone, ensuring consistent curing. Low compression set is an important characteristic of liquid silicone rubber, which makes it ideal for applications where sealing and cushioning are required. The final part of the process is to cure the mixture, which can be done through various methods such as heat or UV light.

Insert Placement

In some cases, the final product may require the incorporation of internal parts or inserts such as gaskets. These inserts, which can be made of various materials, must be properly positioned within the mold before the injection process. The molds are designed with specific features to accommodate the placement of these inserts, ensuring they are properly embedded within the silicone coating during the injection process. If the inserts are not properly positioned, it can lead to defects such as cavity formation, which can compromise the quality of the final product.

Mold Heating

Heating is an essential step in the liquid silicone rubber molding process. The mold is typically warmed through the circulation of water in the mold’s cooling channels or by utilizing electric heaters. This makes the material flow better when it’s injected into the mold. In some cases, a cold runner system may be incorporated to maintain specific areas of the mold at a lower temperature to prevent premature curing or excessive material waste. The temperature required in this process depends on the different materials. The melting point and specific gravity of different materials will lead to temperature differences. The following is the relevant information of some commonly used materials:

| Material | Proportion | Melting point(°C) |

| Epoxy resin | 1.12 to 1.24 | 120 |

| Phenol formaldehyde resins | 1.34 to 1.95 | 120 |

| Nylon | 1.01 to 1.15 | 194 to 265 |

| Polyethylene | 0.91 to 0.965 | 110 to 117 |

| Polystyrene | 1.04 to 1.07 | 170 |

Injection

Once the mold is heated and ready, it is closed, and the liquid injection molding process begins. Putting the silicone mix into the mold with high pressure makes sure it fills up all the mold’s spaces and pathways. How long the injection process takes can vary, and it depends on things like how strong the injection pressure is and how thick the silicone is. Optimal injection parameters are determined through extensive testing and optimization to achieve the desired product quality and prevent oxidation.

Curing

Once the mold gets packed with liquid silicone rubber, the mold’s temperature is meticulously elevated to speed up the curing, or hardening, process.This elevated temperature promotes the crosslinking of the polymer chains within the silicone material, transforming it from a liquid state into a solid state. The cycle time for curing and the temperature are precisely controlled to ensure complete and uniform curing throughout the material. Platinum catalyst is often used to speed up the curing process and ensure a high-quality final product with fast cure.

Cooling and Demolding

Once the curing process is complete, the mold is cooled down to solidify the silicone further. The product is then taken out from the mold, a process which is known as demolding. Depending on the specific cooling requirements, the demolded product may be cooled further in ambient conditions. This final cooling step ensures that the product achieves its final dimensions and properties before it is ready for further processing or use.

Conclusion

Liquid Silicone Rubber (LSR) molding technique provides a number of benefits. It allows for high precision and tight tolerances, making it suitable for producing intricate and complex parts. It also enables the production of parts with consistent quality and performance. Additionally, LSR molding offers excellent temperature resistance, chemical resistance, and biocompatibility, making it suitable for a wide range of applications in various industries such as automotive, medical, electronics, and consumer goods. With its unique properties, LSR materials molding is also ideal for producing lsr parts made of platinum.

If you are prepared to start a new project about liquid silicone rubber molding, please contact Seaskymedical today!