Thin wall injection molding is an incredibly specialized sector of manufacturing that can provide numerous benefits, including reduced cost, faster production cycles, and lighter parts. However, thin-wall injection molding is not without challenges.

This article will delve into the intricacies of thin wall molding, its applications, design guidelines, and best practices to prevent defects and maintain quality. By the end, you’ll have a comprehensive understanding of this complex process and be ready to navigate its intricacies effectively, including the importance of injection pressure.

Introduction to Thin Wall Injection Molding

Thin wall injection molding is a subset of the broader injection molding process, which is widely used in manufacturing due to its versatility and cost-efficiency. Thin wall molding, as the name suggests, involves the creation of parts with thinner walls compared to those produced using traditional injection molding.

The driving factor behind thin wall molding is the demand for lighter, smaller components in various industries.

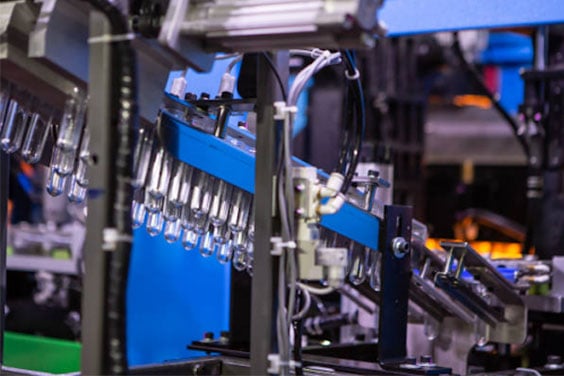

The thin wall molding process requires modifications to standard injection molding procedures. It involves higher pressures and speeds, faster cooling times, and changes to part ejection and gating methods, including high injection speed. As such, it necessitates specialized machines and injection molds, as well as detailed attention to part and mold design.

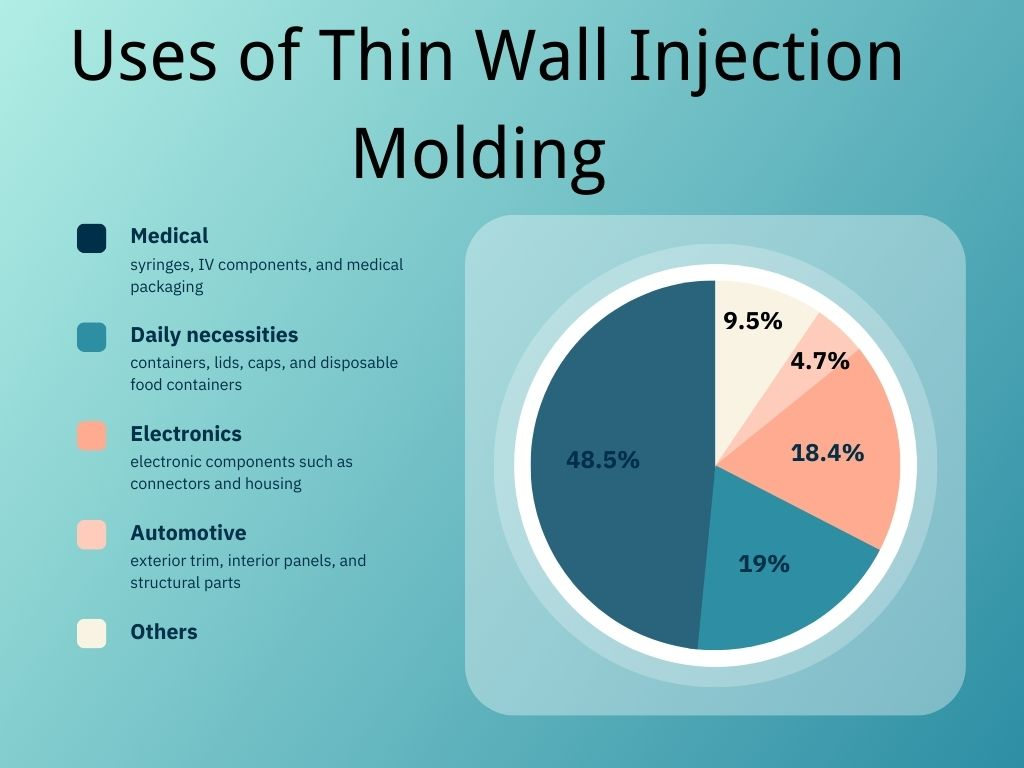

Uses of Thin Wall Injection Molding

Thin wall injection molding is widely used in various sectors, primarily due to its cost and material savings, as well as its ability to produce lightweight parts.

Why Use Thin Wall Injection Molding in Medical Field?

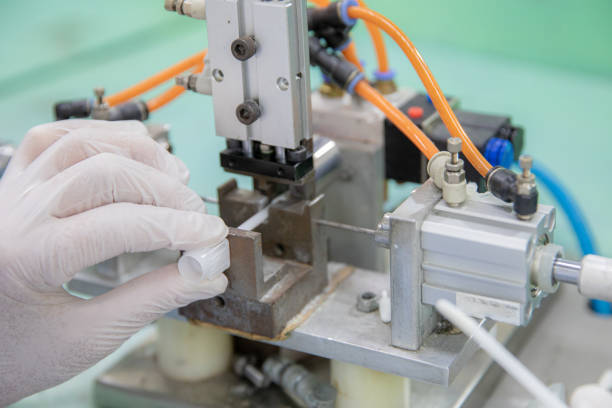

Thin wall molding allows for the efficient production of high volumes of medical components.

The shorter cooling times associated with thin wall molding contribute to improved cycle times, enhancing productivity and reducing manufacturing costs, resulting in faster cycle times and fast cycle times.

This is particularly critical in the medical industry, where the demand for medical devices is often high, and rapid production is necessary to meet patient needs.

Moreover, thin wall molding facilitates the creation of intricate and complex medical designs. Leveraging cutting-edge mold flow analysis and technology, the service provider is able to enhance the mold design. This ensures that the end product fulfills all the necessary functional and safety criteria.

This is particularly important in medical applications where precision and reliability are paramount. Thin wall molding can achieve wall thicknesses as low as one-tenth of an inch, making it an ideal solution for creating intricate and complex medical designs with plastic injection molding and thickness ratio.

Furthermore, the materials used in thin wall molding for medical devices must meet stringent regulatory standards, ensuring biocompatibility, chemical resistance, and sterilization compatibility.

The chosen service provider should have expertise in selecting the appropriate medical-grade materials and adhering to regulatory guidelines to ensure the high quality, safety standards, and sustainability.

Design Guidelines for Successful Thin Wall Injection Molding

Designing parts for thin wall molding involves careful consideration of various factors, including material choice, mold design, wall thickness, and gate design. Here are some guidelines to follow:

Material Selection

The choice of material is crucial in thin wall molding. Some materials, such as polycarbonate, may pose challenges when filling thin-walled molds. However, certain thermoplastics, like high-density polyethylene (HDPE), low-density polyethylene (LDPE), nylon, and polypropylene, flow more readily through thin sections of a mold. It is advisable to select a plastic material that aligns with the part’s application needs and won’t accelerate mold wear when injected at high speeds. One important factor to consider is the flow length and viscosity of the material.

| Resin | Recommended Wall Thickness | |

| Inches | mm | |

| ABS | 0.045–0.140 | 1.14–3.56 |

| Acetal | 0.030–0.120 | 0.76–3.05 |

| Acrylic | 0.025–0.150 | 0.64–3.81 |

| Liquid Crystal Polymer | 0.030–0.120 | 0.76–3.05 |

| Long-Fiber Reinforced Plastics | 0.075–1.000 | 1.91–25.4 |

| Nylon | 0.030–0.115 | 0.76–2.92 |

| Polycarbonate | 0.040–0.150 | 1.02–3.81 |

| Polyester | 0.025–0.125 | 0.64–3.18 |

| Polyethylene | 0.030–0.200 | 0.76–5.08 |

| Polyethylene Sulfide | 0.020–0.180 | 0.51–4.57 |

| Polypropylene | 0.025–0.150 | 0.64–3.81 |

| Polystyrene | 0.035–0.150 | 0.89–3.81 |

| General rule of thumb | 0.040-0.140 | 1.016-3.556 |

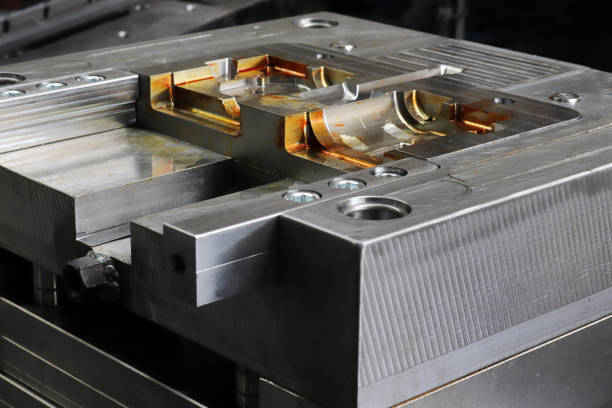

Mold Material and Design

The mold material should be robust enough to withstand the high pressures of thin wall molding. P20 steel, commonly used in conventional injection molding, may not suffice for thin wall molding. More robust materials like 718, H-13, D-2, or other tough steels may be more suitable. However, these materials may increase tooling costs by 30%-40%.

The mold design should also ensure uniform wall thickness throughout the part for even cooling and to prevent defects like warping and sink marks. The use of ribs or gussets can increase part rigidity, while round internal and external corners can prevent parts from sticking to the mold during ejection.

Temperature Control

The adjustment of mold temperature during injection is an important process. A heated mold facilitates smoother plastic flow, thereby enhancing the quality of the part’s surface. To maintain a steady mold surface temperature for cooling purposes, it is advisable to position non-looping cooling lines straight into the core and cavity blocks.

Gate Design

Gates in thin wall molding should be larger than the part’s walls to minimize gate wear and material shear. This also helps prevent freeze-off before packing is achieved. If the gate connects to a thin wall, using a gate well can reduce stress at the gate, improve the filling process, and ease part ejection.

Preventing Defects and Quality Issues in Thin Wall Injection Molding

Thin wall molding can present several challenges, including material flow problems, uneven cooling, warping, cracks, and cosmetic inconsistencies. To prevent these issues, consider the following tips:

- Guarantee consistent wall thickness: This can aid in even cooling and ultimately helps to avoid deformations, sink marks, flow lines, and incomplete injections.

- Design ribs correctly: Incorrectly designed ribs can cause warp, sink marks, voids, and breakage. Ribs should be designed to be 60% of wall thickness or less, with small base radii and enough spacing between ribs.

- Avoid sharp corners: Sharp corners can cause parts to stick to the mold during ejection and can result in voids if there isn’t sufficient pressure. Rounded internal and external corners and edges can ensure a smooth flow of material and a clean ejection.

- Regulate temperature: A warmer mold allows the plastic to flow more easily, resulting in better surface quality. On the other hand, to maintain the utmost consistency in the mold’s surface temperature, cooling lines should be set straight in the core and cavity blocks.

Maintenance Tips for Thin Wall Injection Molding

Maintaining your thin wall injection molding process requires regular checks and preventative measures to ensure optimal performance and quality. Here are some tips:

- Regular mold maintenance: Regularly inspect and clean molds to ensure they are in good condition. This can prevent issues like uneven cooling and part defects.

- Monitor process parameters: Regularly monitor parameters like pressure, temperature, and cycle times to ensure they are within the recommended range. Adjustments may be needed based on the material being used and the part’s design.

- Invest in quality equipment: High-quality, reliable injection molding machines and molds are essential for successful thin wall molding. Regular maintenance and timely upgrades can also contribute to better performance and higher-quality parts.

Thin wall injection molding offers numerous benefits, including cost savings, faster production, and lighter parts. However, it requires careful design, specialized equipment, and regular maintenance to ensure quality and efficiency.

If you have any further inquiries or need additional information regarding thin wall injection molding and the factors to consider in selecting the right service provider, the team at Seaskymedical is more than willing to provide assistance.