Plastic, which is used in thermoforming, comes in different sizes, colors, types, and properties. This is why it’s a preferable option for fabricators and manufacturers, especially medical disposable manufacturers who need lightweight, durable, and clean materials like plastic to make medical equipment.

With thermoforming, manufacturers are provided with a wide range of solutions for processing plastic sheets. Designs, prototypes, and final productions become easier and faster.

In this comprehensive guide, we are going to discuss everything you need to know about thermoforming. Starting from what it is, the types, the processes involved, the types of plastics used, the applications, and so many more.

What is Thermoforming

Thermoforming is a plastic manufacturing method that has to do with heating a plastic sheet and pouring it into a mold to form a precise shape. After the heated plastic is cooled in the mold and the shape is formed, it is then trimmed to get the finished item.

To do this, a thermoforming machine is needed to heat and stretch the malleable plastic sheet over the mold. Formerly, the parts are usually trimmed by manufacturers manually, but with advancements in technology, there are sophisticated thermoforming machines that are equipped to handle the trimming and cutting processes.

In comparison to other manufacturing methods, thermoforming allows fabricators and manufacturers to produce small to wholesale volumes of plastic parts quickly and at an affordable price.

Types of Thermoforming

Thermoforming is an all-in-one manufacturing method that encompasses all the ways manufacturers form heated sheets of plastic. A medical molding company that chooses the vacuum process or the matched mold forming process is taking advantage of thermoforming.

There are many types of thermoforming, but the ones described below are the most common.

- Vacuum Thermoforming: As the name implies, vacuum thermoforming involves the shaping of plastic sheets with a vacuum. Firstly, the plastic sheet is heated to ensure its flexibility. Afterward, the sheet is forced against the mold, thereby removing the air content. This process is well-known for its efficiency and cost-effectiveness.

- Pressure Thermoforming: This type of thermoforming is similar to the vacuum forming process in the sense that it involves heating the plastic sheet and removing the air content with a vacuum. However, there is one more step. Once the air has been removed, a pressing tool is used to apply pressure to the formed plastic to help keep its final shape. Pressure thermoforming is used when a higher level of detailing is required.

- Blow Thermoforming: This has to do with forming and joining of hollow plastic parts. It begins with heating the plastic sheet and then clamping it into the mold. Afterward, air is blown into it. The air pressure presses the molten plastic to match the mold.

- Drape Forming: The molten plastic is draped onto a mandrel with precise patterns. The finished part is formed by pressing the mandrel’s design onto the plastic. In drape forming, little tooling is needed, making it to be cost-effective and it does not result in part weakness as the material thickness is maintained all through.

- Matched Mold Forming: For higher levels of precision, the matched mold forming process is the best as both male and female molds are used to shape the heated plastic sheet. The forming machine pushes the plastic sheet together with the molds, which then take the shape that has been designed.

- Twin Sheet Forming: This type of thermoforming involves generating two layers and joining them to form one single item. To manufacture an item using this style, the plastic sheets are heated simultaneously, molded, and joined with each other. The twin sheet forming method is preferably used to produce hollowed items or items with two walls.

- Billow Forming: Unlike others that require the use of molds to get the desired shape, billow forming is a free-form thermoforming method that does not need a mold. In this forming style, the shaping machine blasts the plastic into a bubble using air jets until the final design is formed.

- Mechanical Thermoforming: Mechanical thermoforming involves shaping the molten plastic sheet with a direct mechanical force. The surface patterns are imprinted on the plastic sheet by forcing the malleable sheet to fill a space between the plug and the mold. This type of thermoforming process is usually used when a high level of detail and precision is needed.

- Plug Assist Forming: In this thermoforming style, a female mold is needed. And to improve the limited depth of the female mold draw, a plug assist is used. Mechanically, the plastic sheet is pre-stretched by a plug that is pressed into the heated plastic. After this, a vacuum is applied to the mold.

What are the Thermoforming Processes

As like any manufacturing method, there are stages of thermoforming. The major stages are designing, prototyping, final tooling, production, and shipping. They are explained below.

- Design: For every quality product, there must be a design that will be followed in production. Designing in thermoforming entails many parts, such as the plastic material selection, planning, and drawing a detailed CAD to guide the manufacturing process. Generally, it has to do with understanding what the project entails and how to make it happen.

- Prototyping: After the designing stage is completed, the next is the making of samples on a small scale. To test the reliability of your design, you have to make a couple of samples. If what you get is not what you desired, you will go back to the drafting table and revisit the designing stage.

- Final Tooling: After the success of the prototyping stage, the next process involved is the inclusion of other tools needed for mass production. Get all the tools you need for mass production, including the plastic materials, molds, and forming machine.

- Mass Production: At this stage, you are fully armed to begin mass production. Following the efficiently drafted design plan, production becomes easier and faster than prototyping. Also, with the availability of the needed tools, production on a large scale is enhanced.

- Shipping: This is the final lap of the thermoforming process. The manufacturing processes are meaningless if the fabricated parts are not delivered to the customers. So, to make the thermoforming process complete, the parts are to be delivered to the customers.

Thick vs. Thin Gauge Thermoforming

The sheet gauges used in thermoforming are usually different. This is dependent on the products that are to be made and the functions they will serve. A thermoformed part can either be thick-gauged or thin-gauged.

- The thick gauge thermoforming, which is also called heavy gauge thermoforming, is fed using thick plastic sheets. The part thickness is usually between 1.5 to 9.5 mm. Some of the common thermoforming materials used are ABS, HDPE, and Polypropylene.

- The thin gauge thermoforming, on the other hand, is carried out using thin sheets from plastic rolls. The part thickness is usually less than 3 mm. Some of the common thermoforming materials used are PET and PVC.

When selecting thermoformed equipment, the gauge of the sheet must be considered, either thick or thin gauged equipment. For instance, manufacturers who carry out medical insert molding or are intended to produce items like plastic cups and food processing make use of thin-gauge thermoforming to produce thinner products. Thin-gauge thermoforming is meant for high-volume production.

On the other hand, items like containers used by heavy industries necessitate thick-gauge thermoforming. While heavy-gauge thermoforming is meant for low to mid-volume production.

Types of Molds for Thermoforming

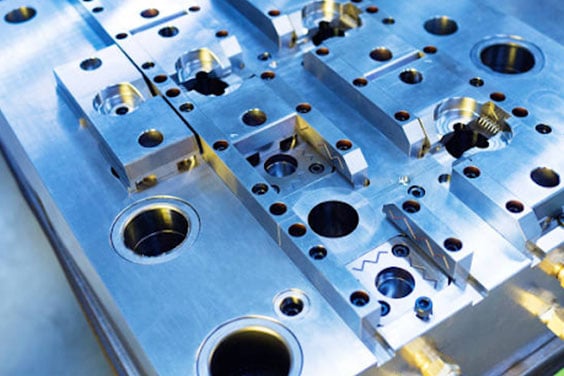

Thermoforming molds are made from different types of materials. Below are the major types of materials used in making molds for thermoforming and how they are constructed.

- Plastic: Plastic molds are very cheap and can be prepared and patched within a short period of time. However, they are not very strong. But the bottom of a cast plastic mold can be strengthened with resin-impregnated fiberglass for additional strength.

- Wood: Using wood for experimental purposes is a common practice. However, caution should be taken to the type of adhesive used for joining parts. In this case, a thermosetting glue is preferable. Also, wooden molds should be covered with epoxy resin and then sanded, and polished for a better surface finish and wear resistance. Applying an epoxy coat on the whole mold will improve the durability by limiting moisture absorption.

- Fiberglass: These molds are usually used to make multiple copies of parts that have complex shapes. Fiberglass molds involve the use of plugs, which aids thermoforming. Layers of fiberglass are applied to the mold, with the resin allowed to cool and form. After that, the wedges are driven between the plug and mold to separate the both of them.

- Aluminum: Thermoforming molds made from aluminum can be made in two methods. Firstly, they can be manufactured from aluminum plate stock and machined to the desired shape. Secondly, they can be cast in aluminum and then machined and finished.

- Sprayed Metal: This mold involves a sprayed metal shell, covered with resin-impregnated backing. They become strong enough that they can produce several millions of parts with no sign of degradation. With this type of mold, you can reproduce parts with accurate details.

Types of Thermoforming Plastic

There are two major types of plastic. They are thermoplastic and thermoset. The former is recyclable and can be remolded into any desired shape, while the latter is not recyclable. For thermoforming, the best plastic-type is thermoplastic as it allows you to recycle, remold, and trim into any shape you want.

Below are the major types of thermoforming plastic:

- Polypropylene (PP): In terms of value and volume, PP is the most popular thermoforming plastic. It’s widely found in packaging, ventilators, toys, and other plastic products. Polypropylene is preferred because of its outstanding properties, such as resistance to chemicals, heat, and fatigue. PP is also a cost-effective material that may be used in a variety of thermoforming processes.

- Polystyrene (PS): Polystyrene is an aromatic hydrocarbon plastic that is transparent, hard, and brittle, making it easy to work with. PS is commonly used as a thermoforming packaging material because of its water and air resistance. It is used in the production of food packaging, jewel cases, CD cases, and household products.

- Polyethylene Terephthalate (PET): Polyethylene Terephthalate has excellent alcohol and essential oil barrier qualities, as well as chemical resistance, impact resistance, and tensile strength. PET is mostly used for carbonated beverages, water bottles, and a variety of food products.

- Low-Density Polyethylene (LDPE): This is a plastic material that is resistant to chemicals and UV rays. It is lightweight and flexible, with high tensile strength. LDPE is used in making items like DVDs, cable insulators, containers, and chemically-resistant products.

- High-Density Polyethylene (HDPE): This plastic is similar to LDPE in terms of its base qualities, and it’s known for its resistance to chemicals, UV rays, and water. But it is stronger, making it suitable for more demanding projects. HDPE thermoplastic can be used to make packaging film, blown bottles, pipelines, containers, and bags.

- Polyvinyl Chloride (PVC): Another common thermoforming plastic is PVC, which is used to make pipes, window frames, automobile interiors, household products, containers, and footwear. PVC can be designed to be hard or flexible depending on the need of the manufacturer. This plastic material is also dense, long-lasting, and water-resistant.

- Polycarbonate (PC): Polycarbonate is a strong and durable plastic that can withstand large deformations without breaking. It’s resistant to heat and flame, and can insulate electricity. Polycarbonate is also optically clear and very transparent to visible light in some grades. The best medical plastic injection molding company closest to you uses this plastic material to make medical equipment and lenses.

- Cellulose Acetate: Cellulose acetate is a colorless, transparent material that’s used to make domestic items, glass frames, and pill coverings. This thermoplastic is manufactured from sustainable materials like wood pulp that has been processed.

- Polymethyl Methacrylate (PMMA): This plastic possesses great strength, durability, weather resistance, and transparency. PMMA is used to make lenses and automobile headlights. Its durability feature ensures that customers can use the products for a very long time.

- Acrylonitrile-Butadiene-Styrene (ABS): This thermoplastic material is widely known for its rigidity and resistance to abrasion and low temperature. Manufacturers prefer using ABS when they want to make products like electronic packaging, household appliances, and food containers.

What are Thermoforming Applications

Thermoforming is used for several purposes in different industries. Below are some of the industries that appreciate what thermoforming is used for.

Medical Device

Plastic thermoformed parts are used for numerous purposes in the healthcare industry. Amongst their many applications are surgical consumables, laboratory components, monitoring equipment enclosures, CT scanner components, structural coverings, and medical device packaging.

Medical PPE

Personal Protective Equipment (PPE), including face masks and shields, are made through clean room injection molding and thermoforming. These components protect people from the transmission of diseases and infections, especially in the hospital.

Transportation

Vacuum forming and pressure forming thermoforming processes are uniquely suitable for fabricating parts needed for transportation purposes in cars, buses, railcars, and aerospace. Examples of thermoforming applications in the transportation industry are seating components, luggage racks, window shrouds, armrests, gallery paneling, etc.

Unmanned Vehicle and Systems

Thermoforming is a cost-effective and lightweight alternative for manufacturing Unmanned Vehicle and System parts. It supports micro injection molding and makes the structural form molding at a very low cost, as well as producing durable parts with great aesthetic designs.

Industrial & Heavy Equipment

Thermoforming provides a rugged, cost-effective, and beautiful solution for industrial & heavy equipment components. With the aid of a CNC mold, the making of industrial & heavy parts becomes faster and more accurate. Furthermore, materials made from thermoforming processes can function perfectly in the harshest environment.

Kiosk and Self Service Vending

Thermoforming produces parts that rival other manufacturing methods in providing detailed, strong, and durable kiosk & self service vending components. Furthermore, thermoforming plastic is more flexible than working with metal, thereby better control during production.

Electronic & Sensor Enclosures

Another application of thermoforming is the making of electronic & sensor enclosures. Examples of the parts produced through thermoforming for this purpose include communication unit enclosures, battery housing covers & trays, antenna enclosures & covers, and traffic monitoring device covers.

Food Service Components

Food service and dispensing components are made with thermoforming plastics that are lightweight, mobile, and durable. They are made to comply with Food and Drug Administration (FDA) standards to ensure their safe usage for consumption.

Thermoforming Advantages and Disadvantages

Now, we are the bottom line i.e., the advantages and disadvantages of thermoforming, and how preferable it is to other manufacturing methods.

Advantages

- Thermoforming produces an excellent surface finish

- Several finished parts can be made from the same material

- There are no parting lines, which makes it different and better than other plastic manufacturing methods

- Once the thermoforming process is completed, there is usually little (if any) additional work to do

- Thin-film production can be done with several materials and it’s most commonly used for industrial packaging

- Allows you to notice the design and fit problems before it’s too late

- Short lead time and cost-effectiveness

- Highly beneficial when dealing with large parts

Disadvantages

- There can be a lot of material wastage

- The cost of the required sheet plastic material is substantially higher than the cost of the raw pellet form

- At sharp angles, the process can produce severe sheet thinning

- Many parameters are worth consideration. Some of them are temperature, clamping force, and vacuum pressure

Equipment Used for Thermoforming

There are three basic thermoforming equipment to choose from, which include industrial, desktop, and DIY thermoforming equipment. They are explained below.

- Industrial Thermoforming Equipment: This is a large-scale machine designed for production at mid-to-high volumes. It’s compatible with a wide range of materials and sheet thicknesses.

Also, industrial thermoforming equipment has a deeper draw and higher vacuum force to fabricate complex and intricate details. The cost is within the range of $10,000 to $100,000. Examples of this kind of equipment are Formech, GN, Ridat, and Belovac vacuum thermoforming machines.

- Desktop Thermoforming Equipment: This type of thermoforming equipment has a smaller dimension, supports a wider range of materials, and applies lower forces. Desktop thermoforming equipment is used by manufacturers and product developers for prototyping, making custom parts, and low-volume production. The cost is within the range of $1,000 to $10,000. Examples of this kind of equipment are Formech, Smartform, and Mayku.

- DIY Thermoforming Equipment: Those interested in experimenting with thermoforming can build their own DIY machine for low-volume production. DIY thermoforming equipment is often less expensive than commercial thermoforming equipment, however, it’s more labor-intensive and requires a lot of experience.

What is Plug Assist Thermoforming

This is a widely used thermoforming method and it requires the use of a female mold for it to be successful. Plug assist is used to enhance the mold’s limited depth of draw.

In manufacturing, the plastic sheet is mechanically pre-stretched by the plug that’s pressed into the heated plastic before the vacuum is applied to the mold. The dimension of the plug is 10 to 30 percent smaller than the interior of the female mold.

Things to Consider When Performing Thermoforming designs

Getting your thermoforming designs accurately is dependent on some factors, and you need to know them so that your thermoforming process will result in the part that you wanted. Below are the things you need to consider when performing thermoforming designs.

- Production Volume: Being certain about the production volume will help in deciding on the type of mold to use. While wood, plaster, plastic, and composite molds are the most cost-effective molds, they are only suitable for low-volume production. Metal molds, on the other hand, are the best option for high-volume production. This is because they have better thermal strength and conductivity.

- Part Design: The complexity of the part determines the types of mold design that will be constructed. For simple molds, handcrafting molds from wood are ideal. On the other hand, parts that have complex shapes and require precision are better handled with casting and digital equipment, such as 3D printing and machining.

- Thermoforming Temperature: The type of material thermoformed will determine the level of the mold thermal resistance. To enhance the cooling rates, cooling channels can be added to the mold. This also improves the uniformity and reduces the cycle time of production

- Thermoforming Forces: The tool must be very strong to endure the forming forces in the thermoforming process, like vacuum forces, pressures, and mechanical operations. The magnitude of these forces is influenced by some factors like the material used, sheet gauge, and part quality requirements.

- Mold Design Features: The mold should be designed to have more features that will ease the thermoforming process. Additional features like multiple ventilation holes for circulating air from the forming process and draft corners to assist in demolding the part.

- Mold Surface Finish: During the thermoforming process, remember to consider the part quality standards like the surface finish, intricacy level, dimensional accuracy, and stability.

- Typical Tolerances: The required tolerance varies as it depends on the type of material that’s used. However, the typical tolerances of part to part forming is +/- .025”, while the perimeter die cut is +/-.060”.

- Tooling Thickness: The thickness of the tool depends on the type of part that’s to be fabricated. If you are manufacturing heavy parts, the tooling must be very thick. Another thing that affects the tooling thickness is the factors they will be exposed to during production.

- Clamping Force: Some thermoforming methods like the pressure forming and matched mold forming methods require that the thermoforming equipment clamps down on the plastic sheet to get the finished part. Knowing the clamping force is very important as it helps decide the type of material that will be used.

- Depth of Draw: Knowing the thermoforming process very well requires an understanding of the depth of draw, which is also known as the draw ratio. The depth of draw informs the manufacturer of the plastic gauge needed for each thermoforming project. By knowing this, the manufacturer will be able to determine the thickness of the plastic part.

- Forming Temperature: The temperature at which the part will be formed should be put into consideration. Will the part be formed at a low temperature in order to get all the intricate details desired or will it be formed at a high temperature?

- Mold Tool Temperature: To produce parts of consistent quality with short cycle times, the mold tool temperature must be regulated. For most applications, coils are put in the mold for the circulation of hot water at the start of production. This boosts the temperature of the mold to the required level. The coils also circulate cold water to remove heat retained by the mold during the thermoforming process.

- Vacuum and/or Air Pressure: Vacuum should be supplied through strategically placed openings in the mold to improve proper thermoforming. The number, sizes, and placement of the openings will be determined by the part design and required detail.

- Liquid or Air Coolant Flow Rate and Temperature: The rate at which liquid and air will be flowing in the mold should be known as it influences the success of the thermoforming process. Ideally, the mold temperature differential should not exceed 5 degrees Fahrenheit between the entrance and exit water.

What are the Differences between Thermosetting and Thermoforming

In simple terms, the major difference that exists between these two processes is heat resistance.

Thermosetting plastics are very rigid, tough, and highly resistant to heat, which is why they are used for applications that will be exposed to a lot of heat. Once melted during manufacturing processes, they can’t be melted again by anything. No matter the level of heat they are exposed to, they won’t re-melt. Examples are melamine, epoxy resin, phenol-formaldehyde, and polyester resin.

Thermoforming, on the other hand, can be heated and formed into different shapes repeatedly. They are very brittle and malleable, making them recyclable and reused. Examples are polypropylene, nylon, polythene, and polyvinyl chloride.